metal slant bed spinning turning cnc lathe machine

- group name

- CNC Lathe

- Min Order

- 1 set

- brand name

- DRC

- model

- IHT5

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C

- update time

- Thu, 14 Nov 2019 13:22:31 GMT

Paramtents

Processing diameter: 390/384/296mm

Weight: 3200kg

Power(W): 7.5/11/15

Dimension(L*W*H): 3400*1850*1800

Speed range: 5-5000

Maximum cutting diameter: 340/330/328/ 310/202 mm

Max. Swing Diameter: 520MM

Spindle motor /FANUC: Engraving Milling Machine

Packging & Delivery

-

Min Order1 set

Briefing

optimal spindle structure design for better performance

Detailed

high precision muti functions slant bed CNC lathe DRC IHT5 CNC Metalworker Mini Lathe Machine

Top1 supplier new metal slant bed spinning turning cnc lathe machine

Product Application:slant bed turret cnc lathe

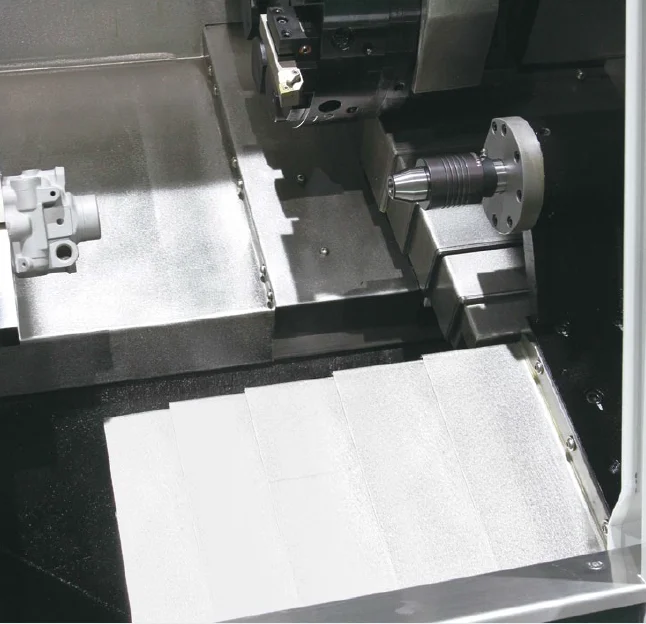

iHT5 Tuning lathe machine with FANUC control system, Included Standard Equipment and Standard Control System Functions. Integrally molded low center of gravity casting bed, 30 ° saddle through optimized design, It has a large shock damping and a smaller amount of deformation, the main axle box, turret. Providing high-rigidity structure basis. 30 ° slant bed design to facilitate the operator upper and lower parts, but also to ensure. Smooth chip evacuation.

Main Features:metal CNC lathe

IHT series Tuning machine with FANUC control system, Included Standard Equipment and Standard Control System Functions. Integrally molded low center of gravity casting bed, 30/45 ° saddle through optimized design, It has a large shock damping and a smaller amount of deformation, the main axle box, turret. Providing high-rigidity structure basis. 30/45 ° slant bed design to facilitate the operator upper and lower parts, but also to ensure. Smooth chip evacuation.

Compact design with HT300 high tension Meehanite cast-iron machine bed.

Perfect accessibility and optimal working depth.

The ideal machine for training, with minimal space requirement and uitable working depth to the spindle.

Increased productivity with up to 12 driven tools ( optional).

Most updated control technology: FANUC Oi-TF with10 4"panel (optional or SIEMENS 828D (840D optional).Spindle bearing lubricant:grease

turning cnc lathe

Integrated Frame Strusture Super rigidity, High effeciency,Ultimate Cutting Capability:

Headstock with heat sink design is integrated casting.

Rigid tapping function as standard to realize high-speed precise tapping without floating tapping collets. Easy to program better tapping ccuracy, offers maximum tapping productivty.

With high performance V-belt driving spindle, make maintenance easier,also reduce the impact of the spindle accuracy from the heat on spindle notor conducting. By adjusting pulley reduction ratio, to synchronize the indle& the motor maximum rpm, thereby reducing the minimum rpm of the maximum power output increasing torque, which maximize spindle motor's potential achieve maximum turning capability.

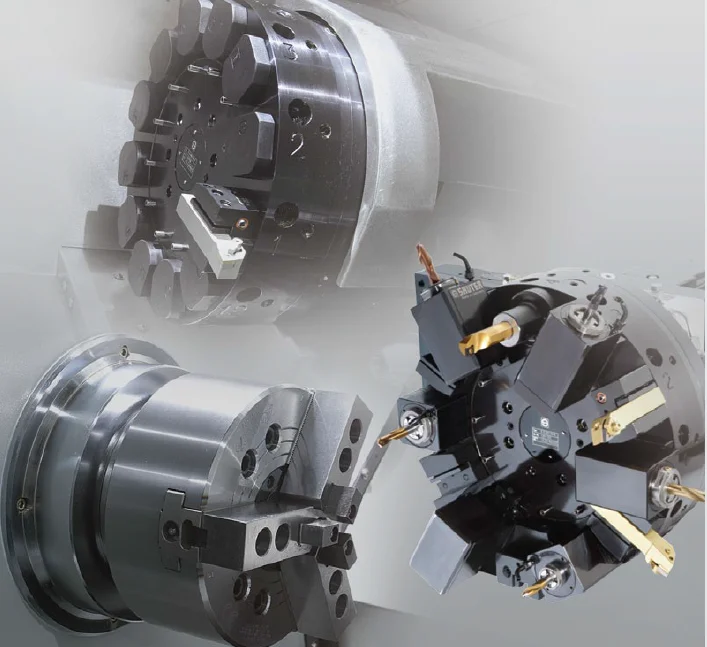

Rich configuration

Electric turret, servo turret, power turret; high-power motors, high torque. Motor; large diameter hollow cylinder; chuck; drawer-type water tank; on the knife;

Oil mist separator and other options are available.

User- friendly design

2. Processing conditions, all surrounded by human aesthetic design, stainless steel cover available for your safety

Modern popullar control packages

High cost performance

German descent i H T series has the best parts, like a knife tower SAUTER, NSK bearings, etc. to ensure high-precision parts, as well as appropriate should the price to have a high cost performance.

iHT Series technology:

High stability and perfect machining results thanks to the integrally molded massive HT300 cast iron bed.

The bigger spindle bearings and the appropriate wide spacing between the guideway ensure that iHT series machines by high accuracy and rigidity.

Slot disk, vDl disk, BMT disk, electric turret, servo turret, servo-driven turret all can choose by the customer.

Hydraulic controlled tailstock, servo tailstock all can choose.

Inner housing made by the stainless steel which can avoid to rust.

Hollow chuck as standard (Closed center chuck optional)

Traversable steady rest (HT10 optional)

COMPANY INTRODUCTION:

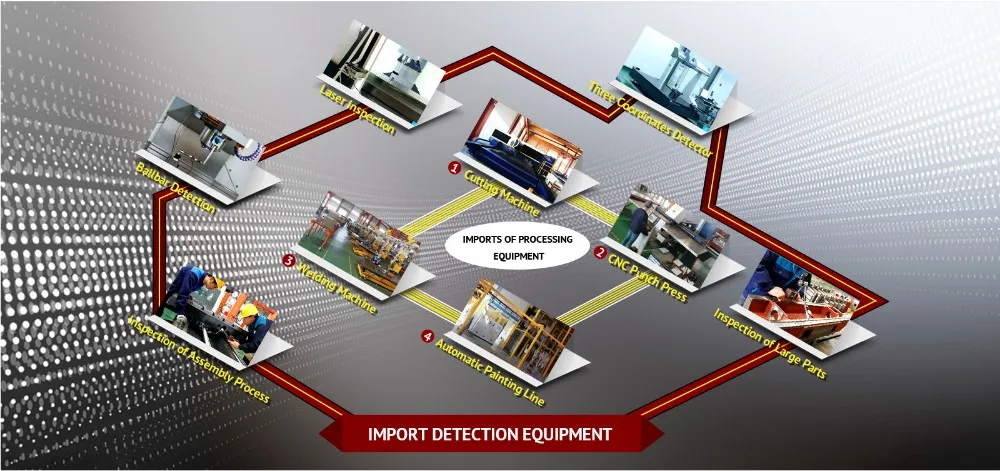

DRC is a group company ,which is professional in products and sales of advanced CNC machine tools . Acting full operation of the six machine tool production company's overseas sales.

DRC is located in Dalian, which is one of the largest seaport cities of China.Our products exported to Russia, Dubai, Hungary, Italy, Argentina, the Philippines, India, Iran, more than 50 countries.

DRC has six factories in China, which covers many kinds of mechanical equipment.

Product Range:

◎CNC Lathe

◎Conventional Lathe,

◎Vertical Lathe

◎Wheel Repair Lathe

◎Planer & Slotting Machines

◎Machine Accessories

◎Machining Center

◎Boring and Milling Machine

◎Dental Milling Machine

◎Glass Tempering Furnace

◎Special Machine for Pipe Threading ,Valve Milling, End Facing and so on

B: MOQ is one set, and warranty is one year.

A: Could you please tell me the payment way of your company?

B:The payment way is general T/T or L/C.

A: Do you have CE or any other certificate?

B: We have certifies, such as CE, Invention patent certificate etc.

A: What is the delivery time?

B: Some models are inshore , some models need about 2 months or more.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China