Planer Type Boring Machine

- group name

- Boring Machine

- Min Order

- 1 piece

- brand name

- DRC

- model

- DBM-130B

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C

- update time

- Thu, 14 Nov 2019 13:23:26 GMT

Paramtents

X-axis travel (standard) 4500mm

X-axis travel (optional) 5500mm

Y-axis travel (standard) 3500mm

Z-axis travel (standard) 2000mm

Z-axis travel (optional) 2500mm

W-axis travel (standard) 700mm

Center of spindle worktable surface 0-3500mm

Nose of spindle to work center 100-2000mm

Spinde diameter 130mm

Spindle taper ISO 50

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

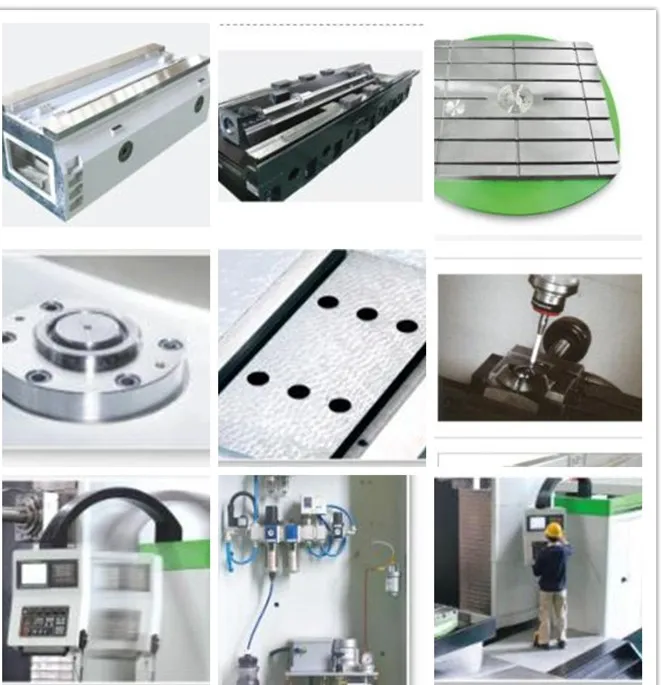

Table Type Boring Machine DBM-130B Planer Type Horizontal Boring Machine - With Ram

Boring Machine DBM-130B Planer Type CNC Horizontal Boring Milling Machine With 5-axis And Heavy Loading Capacity

|

| Boring milling machine with servo moto |

Processing Equipment

|

CNC Planer type Horizontal Boring and Milling Machine Main Futures

Machine tool characteristics

1, the main features

The key parts such as the machine bed and the headstock are made of densely-sealed castings, which are stable in structure and maintain quality forever. The castings are calculated and analyzed by the finite element analysis method, and the reasonable structural strength and the combination of the reinforcing ribs provide high rigidity of the machine. The casting material grade is HT300. The casting structure adopts one-piece molding technology, the box structure, and the large-scale pentahedron processing machine of Japan OKUMA is used for processing. The one-time clamping processing is completed, the machine tool has high rigidity, high strength and excellent geometric position precision. And can guarantee the long-term stability and high precision of the machine.

Note: Casting control of dense baked castings for its application

Casting control of Meehanite Metal Casting: The dense metal castings are subjected to a series of strict casting control, such as the control of graphite carbon (GC) and combined carbon (CC) content in iron; the quality of molten iron metallurgy is Control of Cleanness and Under Cooling Degree; control by Wedge Value after inoculation with CA-SI; control of 5 elements, alloying elements and nitrogen (N) content Etc., it is easy to obtain the expected distribution of the Borne iron base and graphite after casting, and improve the mechanical properties.

In addition, in order to prevent deformation after processing, the castings are completely annealed to facilitate the elimination of internal stress.

Application of HT300:

The densely baked HT300 type is most suitable for casting homogeneous castings with a thickness of 10-15mm. These materials are compact, strong in strength, suitable in hardness, low in friction coefficient, and self-lubricating. Therefore, after surface hardening treatment, they are widely used on workpieces where metal surfaces rub against each other and cause thermal shock, such as tool machine body. , head seat, table top, etc., has a wide range of uses.

2, column

Column-type heavy-duty cutting structure, the column guide rail adopts rectangular hard rail design, the surface of the guide rail is subjected to high-frequency heat treatment, the surface hardness is HRC50°, and after high-precision surface grinding treatment, the full stroke straightness is 10μm, and the sliding surface is pasted with Turcite-B material. The surface of the rail is smoother and wear resistant. The widened hard rail design ensures the resistance and stability required for heavy cutting.

3, headstock, spindle

The headstock is specially designed with high strength and high rigidity cage and keel rib structure.

The main shaft adopts German A.M technology, chrome molybdenum alloy steel material, tempered, rough finishing, carburizing treatment, aging treatment and precision grinding; high precision, strong rigidity and not easy to deform. High output servo motor (30kw) with a maximum speed of 3000rpm. After the spindle assembly is completed, it is corrected by dynamic balance test.

4, weight

The mechanical counterweight design further enhances the stability of the spindle head during operation.

5, the workbench

Standard 2500×2500 continuous rotary table, 0.001° segmentation accuracy, strong bearing capacity (loading 20T), 4×90° cone pin positioning, automatic hydraulic locking, digital control AC servo motor with worm gear system Good backlash compensation; B-axis configuration angle encoder (±5′′), full-closed control, digital information feedback agile, high repeatability.

6, the guide rail:Planer Type Boring Milling Machine

The X and Z axis slides adopt heavy-duty linear roller guides. (X, Zφ65W) has good rigidity, high precision and long service life.

The three axes are all φ80mm (φ80XP10), C3 precision ball screw and P4 bearing, and the positioning accuracy is good.

The X, Y and Z transmission modes adopt direct-connection transmission, which has rapid transmission, stable precision, eliminate backlash, improve torsional rigidity, allow angles to be non-parallel, eliminate axial error, etc., and greatly improve the positioning accuracy of the machine tool.

The Y-axis straight knot drive is combined with the German reducer to improve the torque rigidity.

7, lubrication:cnc planer type milling machine for metal work

Automatic lubrication system, using closed-end continuous oiling machine CEVB-4L, 220V, can ensure sufficient lubricating oil for each lubrication point; each sliding surface and ball screw are distributed according to the oil circuit, respectively control the oil quantity, the circulation lubrication time can be as needed The setting is accompanied by a low oil control device. The cooling water tank uses a split design that makes the chips easy to clean and the cooling water easy to replace.

8, iron filings removal: Planer Type CNC Milling Boring Machine

The spiral chip remover is mounted behind the Z-axis base to facilitate the removal of large amounts of iron filings that fall into the processing area.

DRC is a group company ,which is professional in products and sales of advanced CNC machine tools . Acting full operation of the six machine tool production company's overseas sales.

DRC is located in Dalian, which is one of the largest seaport cities of China.Our products exported to Russia, Dubai, Hungary, Italy, Argentina, the Philippines, India, Iran, more than 50 countries.

DRC has six factories in China, which covers many kinds of mechanical equipment.

Product Range:

CNC Lathe

Conventional Lathe,

Vertical Lathe

Machining Center

Wheel Repair Lathe Machine

Planer & Slotting Machines

Machine Accessories

Boring and Milling Machine

Laser Cutting Machine

Dental Milling Machine

Glass Tempering Furnace

Special Machine for Pipe Threading ,Valve Milling, End Facing Machine and so on

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

During the warranty period, because of product quality problems, the company is responsible for free maintenance, if need to change parts, we be responsible for free replacement.

If the machine problem is not belonging to our machine quality problems, when the buyer needs us send engineers to give repairing service, we charge the appropriate cost.

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer’s installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

6.What's the trade assurance?

When you look at our alibaba website, you will see the trade security, its purpose is to let every buyer confidence, it can protect your payment, ensure that the suppliers fulfill their commitment to the date of shipment and the quality of the products (as you stated in the purchase order).

If the supplier finds breach of these contractual obligations, alibaba will indemnify you for 100% of your trade guarantee.

Therefore, I believe that through trade guarantees, you will have greater confidence to cooperate with us.

Our company has US $128000' trade assurance limit, it can guarantee your interests.

7.Do your products support trade assurance?

Yes, our products are all supported.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China

Horizontal boring and milling machining center\