Big Slant Bed CNC Lathe Machine

- group name

- CNC Lathe

- Min Order

- 1 set

- brand name

- DRC

- model

- IHT1025

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C

- update time

- Sun, 24 May 2020 15:56:46 GMT

Paramtents

Max. Spindle Speed (r.p.m): 3000rpm

Automatic Grade: Automatic lathe

Power(W): 7.5/11/15kw

Max. Swing Diameter: 520MM

spindle hole diameter: 102mm

Machine bed diameter: 680mm

Precision: High Precision lathe Machine

Dimension(L*W*H): 5100*2100*2100mm cnc lathe machine

Speed range: 5-3000

Weight: 7500kg

Packging & Delivery

-

Min Order1 set

Briefing

Detailed

High Rigidity High Precision CNC Turning Center IHT1025 Big Slant Bed CNC Lathe Machine Price

DRC Brand High Efficiency IHT516 Fanuc CNC Chinese Mini Metal Lathe

iHT series lathe Product Application

The IHT series has an excellent rigid structure and a modern control system. IHT has an excellent price/performance ratio, a user-friendly design and a rich configuration. The series uses a self-developed spindle structure to achieve better performance. The fuselage structure is optimized for integration, high rigidity, high efficiency, and high cutting capacity.

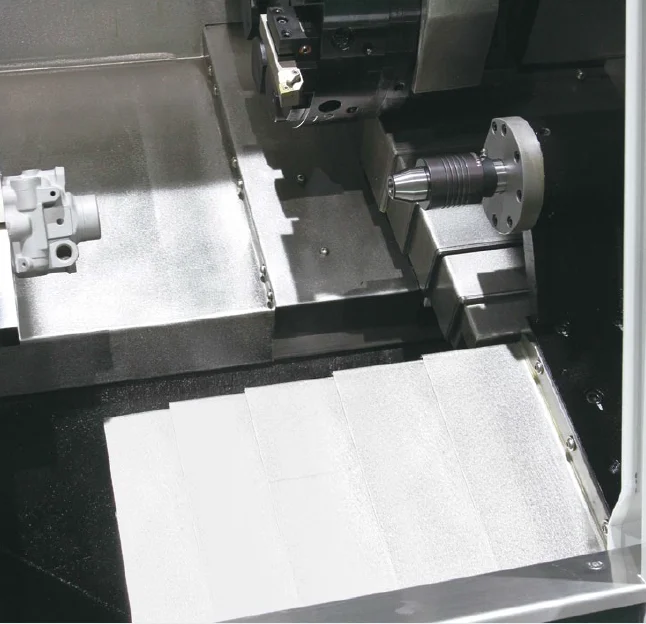

iHT516 Tuning machine with FANUC control system, Included Standard Equipment and Standard Control System Functions. Integrally molded low center of gravity casting bed, 30 ° saddle through optimized design, It has a large shock damping and a smaller amount of deformation, the main axle box, turret. Providing high-rigidity structure basis. 30 ° slant bed design to facilitate the operator upper and lower parts, but also to ensure. Smooth chip evacuation.

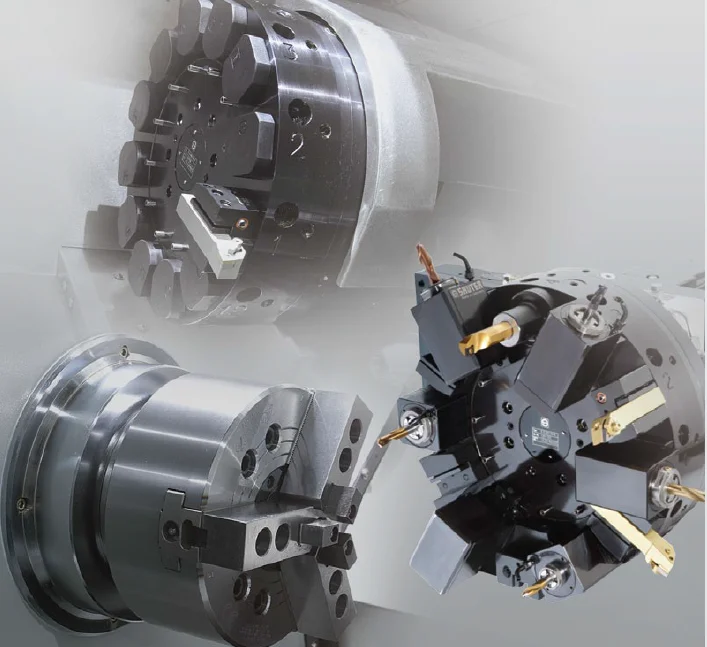

iHT series cnc lathe Main Features

Compact design, HT300 grade gray cast iron bed

Best of proximity and operating depth

Ideal tool for training, covers an area of only 3.5m2, spindle operating depth of only 350mm

Achieve higher productivity by up to 12 driven tools (optional)

The latest CNC technology: FANUC 0i-TF produced the latest operating system with 10.4 "control panel (optional) or

SIEMENS 828D CNC system (840D optional)

Using self-developed spindle structure

Achieve better performance

iHT 516 / iHT 521 / iHT 1025

iHT series lathe of technology

By rail HT300 is equipped with four solid material gray cast iron bed to achieve

Maximum stability and perfect machining results

In the process, the Φ32 mm by 360mm and a ball screw drive

Widely spaced rails for maximum stability

(IHT 1025: 400mm and Φ40 mm)

The maximum internal diameter of up to 100mm spindle bearings

(IHT 1025 as a Φ140 mm), and an optional linear encoders, these ligands

Set so that the aircraft has the highest accuracy and stability

12 tool turret VDI 30 or VDI 40 (BMT optional), standard hydraulic control

System tailstock

Standard hollow hydraulic clamping system (solid optional)

Mobile center frame (optional) and servo-driven tailstock (optional)

SIEMENS, HEIDENHAIN, Bosch Rexroth, Balluff Sauter.

Using high-quality components from Germany

Such as control systems, measuring systems, hydraulic systems, proximity switches and turret from:SIEMENS

1. High stability, solid cast iron frame, compact design -30 ° / 45 ° inclined bed

2. The self-developed spindle structure

3. with programmable hydraulic tailstock iHT 516 / iHT 521 processing space

4. Make-axis machining on a single power tool equipped iHT 1025

5. The integrated finished parts pick means

6. For iHT 1025, on the vertical rail-centering hydraulic steady rest

7. The tool measuring

8. Japan NACHI hydraulic system

Rich configuration

Electric turret, servo turret, power turret; high-power motors, high torque

Motor; large diameter hollow cylinder; chuck; drawer-type water tank; on the knife;

Oil mist separator and other options are available.

Excellent rigid structure:

Integrally molded low center of gravity casting bed, 30 ° saddle through optimized design,

It has a large shock damping and a smaller amount of deformation, the main axle box, turret

Providing high-rigidity structure basis.

30 ° slant bed design to facilitate the operator upper and lower parts, but also to ensure

Smooth chip evacuation.

Modernization of control systems:

High cost performance

German descent i H T series has the best parts, like a knife tower

SAUTER, NSK bearings, etc. to ensure high-

precision parts, as well as appropriate

Should the price to have a high cost.

User-friendly design:

Not only minimum space requirements but also to meet the work area to the maximum extent

Processing conditions, all surrounded by human aesthetic design, stainless steel cover available for your safety

Full clean space, but also to guarantee the durability of the lathe.

Super cutting capacity

Powerful spindle box with heat sink design as one piece casting.Standard features rigid tapping without floating tap chuck to high Speed precision tapping. Programmed depth is more simple and tapping Precise, providing maximum productivity tapping operations.A dedicated high-performance V-belt drive spindle, so that maintenance becomes Easier, but also reduces the accuracy of the spindle motor generates heat Impact. Precision adjustment by pulley reduction ratio, so that the motor.The maximum speed and maximum spindle speed while achieving, thereby reducing.Full power output of the minimum speed and increasing torque, the motor charge

To fulfill their potential and achieve the maximum turning capability.

GV8 HIgh speed vertical machining center

MVL1060 Vertical machine center

DBM110 Horizontal boring and milling machine

COMPANY INTRODUCTION:

DRC is a group company ,which is professional in products and sales of advanced CNC machine tools . Acting full operation of the six machine tool production company's overseas sales.

DRC is located in Dalian, which is one of the largest seaport cities of China.Our products exported to Russia, Dubai, Hungary, Italy, Argentina, the Philippines, India, Iran, more than 50 countries.

DRC has six factories in China, which covers many kinds of mechanical equipment.

Product Range:

◎CNC Lathe

◎Conventional Lathe,

◎Vertical Lathe

◎Machining Center

◎Machine Accessories

◎Planer & Slotting Machines

◎Wheel Repair Lathe Machine

◎Boring and Milling Machine

◎Dental Milling Machine

◎Glass Tempering Furnace

◎Special Machine for Pipe Threading ,Valve Milling, End Facing and so on

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China