Wheel Repair Lathe

- group name

- Wheel repair lathe

- Min Order

- 1 piece

- brand name

- DRC

- model

- RC20QQ

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C

- update time

- Thu, 17 Oct 2019 15:54:20 GMT

Paramtents

Machine Type: Wheel CNC Lathe

Control system: Touch screen

Spindle speed: 50-1800rpm Car wheel repair

Max. Swing Diameter: 23 Inch rim repair cnc lathe

Dimension(L*W*H): 1900×1400×1750mm

Function: Car Wheel Repairing Lathe

Weight: 1300kg wheel rims repair lathe machine

Spindle speed: 150-2000rpm lathe machine

hinery overseas Machine Type: Wheel CNC Lathe

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Factory High Precision Wheel Repair Lathe DRC20QQ wheels refurbished CNC machine

Laser scanning alloy precision wheel repair lathe machine price

What Is The Specifications Of DRC's Wheel Repairing Lathe?

DRC High Performance Wheel Repair Lathe Description:

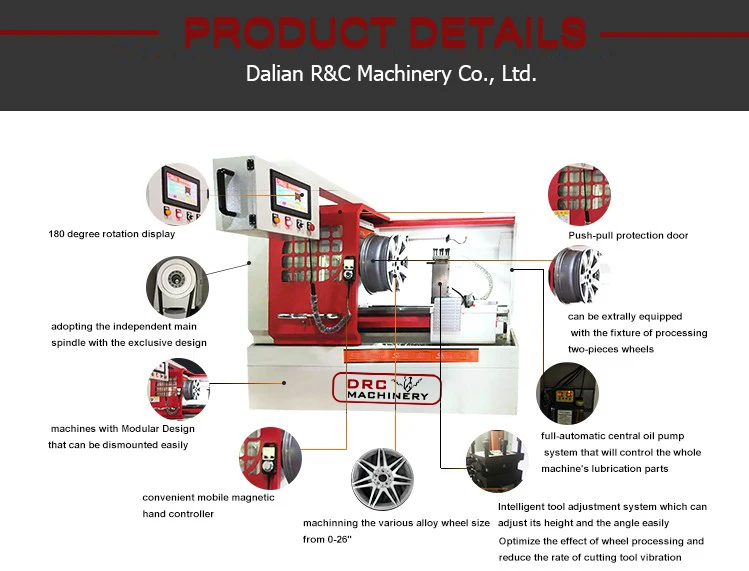

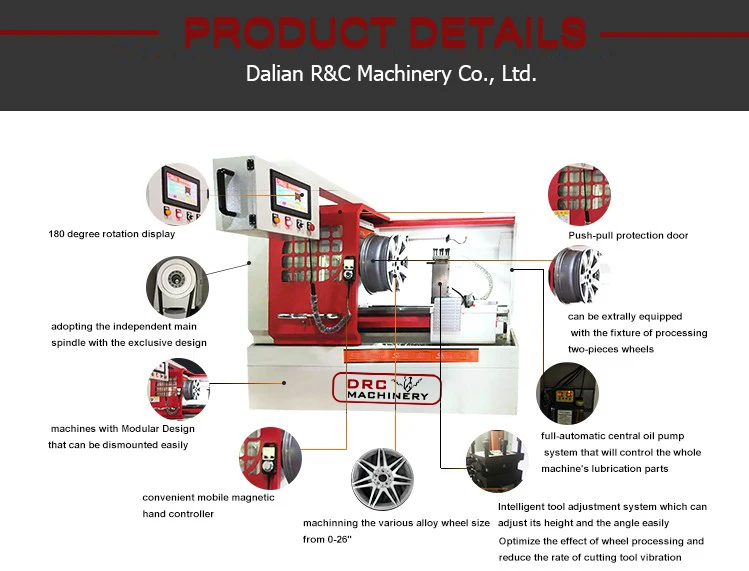

High Performance Wheel Repair Lathe is specially engineered and fabricated wheel CNC machine by DRC Machinery for alloy car wheel repair and maintenance in Car Repair Workshops. New type Economical Alloy Wheel Repair CNC Lathe is composed of self-made mechanical parts such as the cast bed, spindle, fixing chuck and the feeding mechanism, the imported numerical control system, the automatic measuring system, the famous brand servo motors and the auxiliary parts like lubrication, light and cooling.

DRC High Performance Wheel Repair Lathe features self developed CNC system, high efficiency, compact structure, touch screen, easy to operation. High Performance Wheel Repair Lathe DRC20QQ Technical parameters and configuration:

High Performance Wheel Repair Lathe is specially engineered and fabricated wheel CNC machine by DRC Machinery for alloy car wheel repair and maintenance in Car Repair Workshops. New type Economical Alloy Wheel Repair CNC Lathe is composed of self-made mechanical parts such as the cast bed, spindle, fixing chuck and the feeding mechanism, the imported numerical control system, the automatic measuring system, the famous brand servo motors and the auxiliary parts like lubrication, light and cooling.

DRC High Performance Wheel Repair Lathe features self developed CNC system, high efficiency, compact structure, touch screen, easy to operation.

DRC20Q Main feature

DRC Hot Sale Wheel Repair Equipment Description

DRC Hot Sale Wheel Repair Equipment is specially engineered and fabricated wheel CNC machine by DRC Machinery for alloy car wheel repair and maintenance in Car Repair Workshops. Hot Sale Wheel Repair Equipment is composed of self-made mechanical parts such as the cast bed, spindle, fixing chuck and the feeding mechanism, the imported numerical control system, the automatic measuring system, the famous brand servo motors and the auxiliary parts like lubrication, light and cooling.

DRC Hot Sale Wheel Repair Equipment features self developed CNC system, high efficiency, compact structure, touch screen, easy to operation.“DRC Machinery” wheel repair curve optimization software features

1. The software has two-way curve optimization features of the X and Z direction, can achieve the curve optimization of the wheel face and circumference (rim) surfaces.

2. According to the wheel CAD drawings, modified the curves be generated by collection points of the wheel surface.

modify the curve of measurement acquisition point generating of wheel surface.

3. According to the point of collection from the surface of the wheel, you can automatically generate a curve, you can also manually modify and optimize the curve.

4. The software can display multiple languages, adapt to customers in different countries.

5. The software is self-developed, design can be personalized according to customer requirements.

6. The software requires no special installation, open to use, operation is very simple.

7. The software enables to a self-set for safety distance of advance and retreat knife.

DRC Hot Sale Wheel Repair Equipment is specially engineered and fabricated wheel CNC machine by DRC Machinery for alloy car wheel repair and maintenance in Car Repair Workshops. Hot Sale Wheel Repair Equipment is composed of self-made mechanical parts such as the cast bed, spindle, fixing chuck and the feeding mechanism, the imported numerical control system, the automatic measuring system, the famous brand servo motors and the auxiliary parts like lubrication, light and cooling.

DRC Hot Sale Wheel Repair Equipment features self developed CNC system, high efficiency, compact structure, touch screen, easy to operation.

1. The software has two-way curve optimization features of the X and Z direction, can achieve the curve optimization of the wheel face and circumference (rim) surfaces.

2. According to the wheel CAD drawings, modified the curves be generated by collection points of the wheel surface.

modify the curve of measurement acquisition point generating of wheel surface.

3. According to the point of collection from the surface of the wheel, you can automatically generate a curve, you can also manually modify and optimize the curve.

4. The software can display multiple languages, adapt to customers in different countries.

5. The software is self-developed, design can be personalized according to customer requirements.

6. The software requires no special installation, open to use, operation is very simple.

7. The software enables to a self-set for safety distance of advance and retreat knife.

DRC Wheel repair curve optimization software features

High Performance Wheel Repair Lathe DRC20QQ Features:

1. The Alloy Wheel Repair CNC Lathe's control system is a specially developed CNC system by DRC Macxhinery for the wheel repair lathe. It uses a liquid crystal touch screen operation, make up for the universally system's shortcomings for the wheel repair, professional is strong, full functions, good performance, easy to operate.

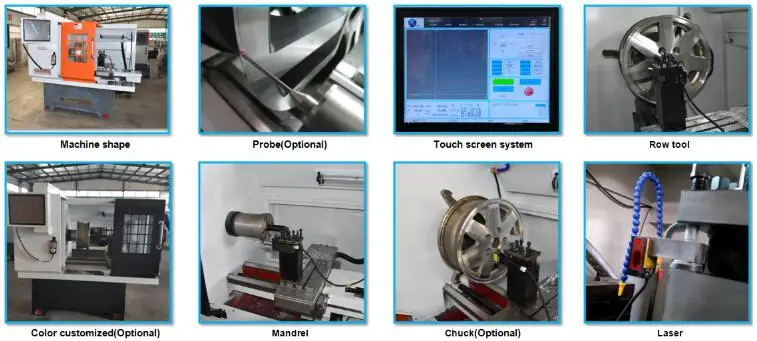

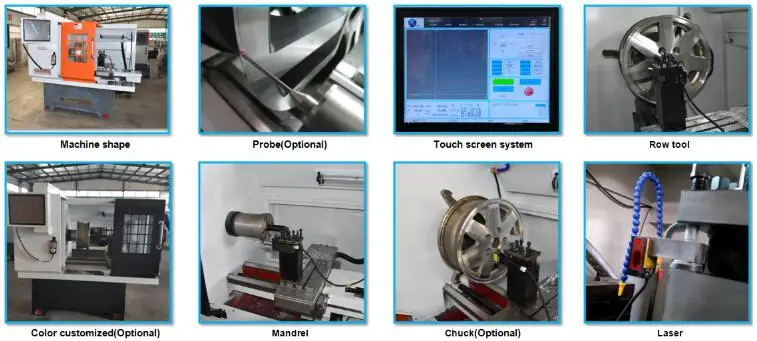

2. The wheel repair machine can meet both the touch probe and the laser non-contact measurements. Laser measurements can be used for intermittent measurements of points, as well as for rapid and continuous scanning measurements. The depth of the wheel surface is not limited by the size of the probe, nor is the loss of the probe.

3. The program optimization is in the system of computer to complete, the operation is very simple.don't need another computer.

4. DRC Macxhinery Wheel Repair Lathe system has teaching programming function, not only can complete the whole surface of the wheel hub repair, but also through teaching to repair the part of the wheel hub.

5. The wheel machine uses wheel specific fixtures, when the wheel clamping, rim positioning and center hole positioning are , allowed, the user optional.

6. The wheel cnc machine door is manual or pneumatic, you can choose.

7. The alloy wheel repair cnc machine case is fully protected.

8. The system interface language can be set according to customer requirements.

9. The dedicated CNC system used by this machine is constantly innovating. Our company promises free upgrade after the sale, and can realize online remote operation, debugging, teaching and technical services.

DRC has many models of Wheel Repairing Lathe to meet your needs, welcome to send an inquiry for more product information.Features:

DRC has many models of Wheel Repairing Lathe to meet your needs, welcome to send an inquiry for more product information.Features:

1. The machine control system is a specially developed CNC system by DRC company for the wheel repair lathe. It uses a liquid crystal touch screen operation, make up for the universally system's shortcomings for the wheel repair, professional is strong, full functions, good performance, easy to operate.

2. The machine can meet both the touch probe and the laser non-contact measurements. Laser measurements can be used for intermittent measurements of points, as well as for rapid and continuous scanning measurements. The depth of the wheel surface is not limited by the size of the probe, nor is the loss of the probe.

3. The program optimization is in the system of computer to complete, the operation is very simple.don't need another computer.

4. system has teaching programming function, not only can complete the whole surface of the wheel hub repair, but also through teaching to repair the part of the wheel hub.

5. The machine uses wheel specific fixtures, when the wheel clamping, rim positioning and center hole positioning are , allowed, the user optional.

6. The dedicated CNC system used by this machine is constantly innovating. Our company promises free upgrade after the sale, and can realize online remote operation, debugging, teaching and technical services.

High Performance Wheel Repair Lathe DRC20QQ Features:

1. The Alloy Wheel Repair CNC Lathe's control system is a specially developed CNC system by DRC Macxhinery for the wheel repair lathe. It uses a liquid crystal touch screen operation, make up for the universally system's shortcomings for the wheel repair, professional is strong, full functions, good performance, easy to operate.

2. The wheel repair machine can meet both the touch probe and the laser non-contact measurements. Laser measurements can be used for intermittent measurements of points, as well as for rapid and continuous scanning measurements. The depth of the wheel surface is not limited by the size of the probe, nor is the loss of the probe.

3. The program optimization is in the system of computer to complete, the operation is very simple.don't need another computer.

4. DRC Macxhinery Wheel Repair Lathe system has teaching programming function, not only can complete the whole surface of the wheel hub repair, but also through teaching to repair the part of the wheel hub.

5. The wheel machine uses wheel specific fixtures, when the wheel clamping, rim positioning and center hole positioning are , allowed, the user optional.

6. The wheel cnc machine door is manual or pneumatic, you can choose.

7. The alloy wheel repair cnc machine case is fully protected.

8. The system interface language can be set according to customer requirements.

9. The dedicated CNC system used by this machine is constantly innovating. Our company promises free upgrade after the sale, and can realize online remote operation, debugging, teaching and technical services.

1. The machine control system is a specially developed CNC system by DRC company for the wheel repair lathe. It uses a liquid crystal touch screen operation, make up for the universally system's shortcomings for the wheel repair, professional is strong, full functions, good performance, easy to operate.

2. The machine can meet both the touch probe and the laser non-contact measurements. Laser measurements can be used for intermittent measurements of points, as well as for rapid and continuous scanning measurements. The depth of the wheel surface is not limited by the size of the probe, nor is the loss of the probe.

3. The program optimization is in the system of computer to complete, the operation is very simple.don't need another computer.

4. system has teaching programming function, not only can complete the whole surface of the wheel hub repair, but also through teaching to repair the part of the wheel hub.

5. The machine uses wheel specific fixtures, when the wheel clamping, rim positioning and center hole positioning are , allowed, the user optional.

6. The dedicated CNC system used by this machine is constantly innovating. Our company promises free upgrade after the sale, and can realize online remote operation, debugging, teaching and technical services.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China