What Is DRC's MV series Vertical Machining Center?

MV series is line rail series, vertical machining center.Mainly used in medium-sized parts and molds, the workpiece in fixture maybe for the completion of milling, drilling, boring, it can be single used and can also be used for multiple operations on parts in a production line, Cutting with powerful, high-speed positioning mechanical and electrical integration, automatic Chip control and security protection feature.

What Is The Application Field of MV series Vertical Machining Center?

( More Detailed Picture of MV series Machining Center )

Strong spindle, ensure perfect processing

The gear type spindle variable speed device provides powerful torque during operation at low speed and guarantees stable rotation during operating at high speed so as to enable wider machining range.By enlarging thickness and diameter of spindle ends and flanges, the spindle with roller bearing not only strengthens all factors related to spindle system, but also improves cutting performance via clamping force of powerful tools.

Win in power

Optional spindle:

BT40:8000/10000r/min Belt-drive 12000/15000r/min Direct-drive

BT50:6000r/min Belt-drive

What Is The Details Of MV series Vertical Machining Center?

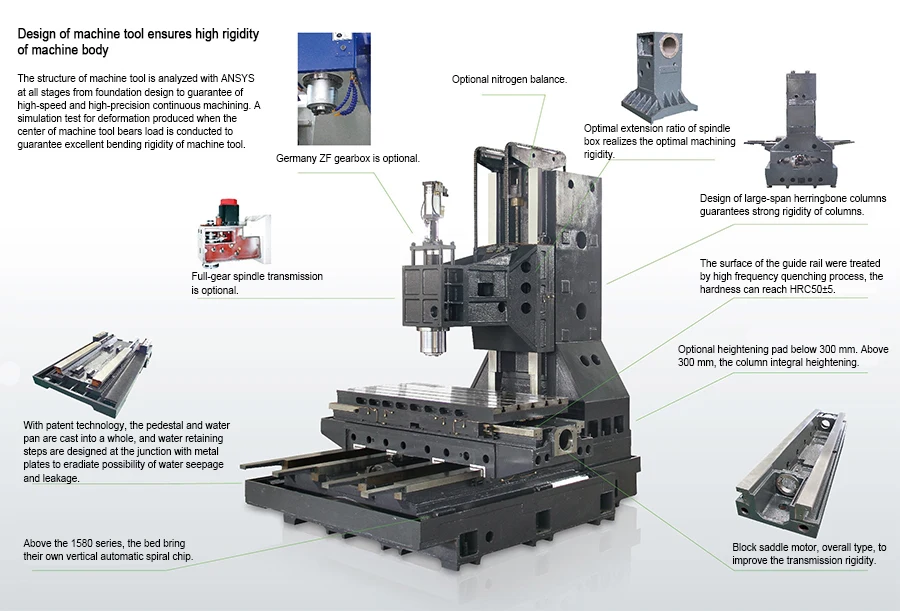

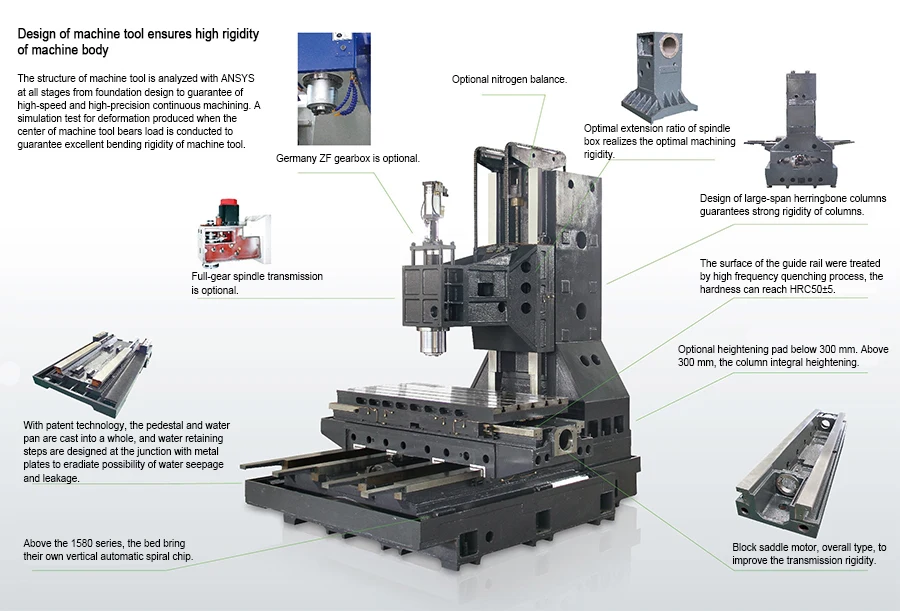

1.Design of machine tool ensures high rigidity of machine body

2.With patent technology, the pedestal and water pan are cast into a whole, and water retaining steps are designed at the junction with metal plates to eradiate possibility of water seepage and leakage.

3.Block saddle motor, overall type, to improve the transmission rigidity.

4.The surface of the guide rail were treated by high frequency quenching process, the hardness can reach HRC50±5.

5.Design of large-span herringbone columns guarantees strong rigidity of columns.

6.Optimal extension ratio of spindle box realizes the optimal machining rigidity.

Who Is DRC?

DRC is a group company ,which is professional in products and sales of advanced CNC machine tools . Acting full operation of the six machine tool production company's overseas sales.

DRC is located in Dalian, which is one of the largest seaport cities of China.Our products exported to Russia, Dubai, Hungary, Italy, Argentina, the Philippines, India, Iran, more than 50 countries.

DRC has six factories in China, which covers many kinds of mechanical equipment.

Product Range:

CNC Lathe

Conventional Lathe,

Vertical Lathe

Machining Center

Boring and Milling Machine

Laser Cutting Machine

Dental Milling Machine

Glass Tempering Furnace

Special Machine for Pipe Threading ,Valve Milling, End Facing Machine and so on

FAQ

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

During the warranty period, because of product quality problems, the company is responsible for free maintenance, if need to change parts, we be responsible for free replacement.

If the machine problem is not belonging to our machine quality problems, when the buyer needs us send engineers to give repairing service, we charge the appropriate cost.

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer’s installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

6.What's the trade assurance?

When you look at our alibaba website, you will see the trade security, its purpose is to let every buyer confidence, it can protect your payment, ensure that the suppliers fulfill their commitment to the date of shipment and the quality of the products (as you stated in the purchase order).

If the supplier finds breach of these contractual obligations, alibaba will indemnify you for 100% of your trade guarantee.

Therefore, I believe that through trade guarantees, you will have greater confidence to cooperate with us.

Our company has US $128000' trade assurance limit, it can guarantee your interests.

7.Do your products support trade assurance?

Yes, our products are all supported.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China

Send Inquiry Here to Get a Free Work-piece Sample!

What Is The Specifications Of MV series Vertical Machining Center?

Machine Type | unit | MV855 | MV1060 | MV1165 |

Worktable |

Worktable(length×width ) | mm | 1050X520 | 1300X600 | 1300X650 |

Maximum load of table | kg | 700 | 1000 | 1000 |

T-slot(number of slot×slot×pitch) | mm | 5-18×80 | 5-18X120 | 5-18X120 |

Triaxial itinerary |

Travel for X/Y/Z axes | mm | 850/550/600 | 1000/600/650 | 1100/650/650 |

Distance from spindle nose to table surface | mm | 150-750 | 150-800 | 150-800 |

Distance from spindle center to column guide surface | mm | 620 | 700 | 750 |

Feed system |

CNC system | | FANUC -Oi MF |

Rapid shift of axes of X/Y/Z | m/min | 30/30/20 | 24/24/20 | 24/24/20 |

Maximum cutting feed speed | m/min | 12 | 8 | 8 |

Standard tool quantity | | Disc 24 |

The larges diamter cutter knife/length | mm | Φ80/300 |

Tool exchaing manner | | Pneumatic |

Average tool exchanging time | sec | Disc 2.5s |

Precision |

Positioning accuracy | mm | 0.008 |

Accuracy of repeated positioning | mm | 0.005 |

Spindle system |

Spindle speed | r.p.m | 8000 |

Spindle specifications (mode /installation /diamter) | | BT40/150 |

Drive manner of spindle | | Belt |

Motor power of spindle | kW | 11/15 |

Air pressure |

Air pressure flux | | ≥0.3 |

Machine specifications |

Integrated weight(kg) | kg | 5200 | 7000 | 7500 |

Overall dimension (length×width×height) | mm | 2700x2300x2600 | 3500x2700x2650 | 3500x2700x2650 |

Send Inquiry Below to Get a Free Work-piece Sample!

Send Inquiry Below to Get a Free Work-piece Sample!