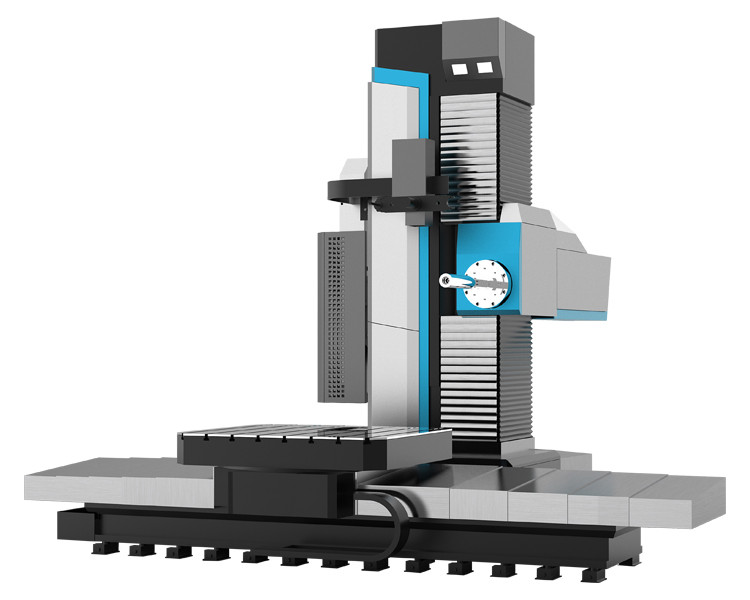

Floor Type Boring And Milling Machine

- group name

- Boring Machine

- Min Order

- 1 piece

- brand name

- DRC

- model

- TK6913

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C

- update time

- Mon, 30 Sep 2019 16:00:10 GMT

Paramtents

Boring spindle diameter: 130

Size of ram section: 380/380

Vertical travel of boring head (Y axis): 2000-4000

Power(W): 22/30 Kw

Total travel of boring spindle and ram: 1500

Spindle speed: 2-1000(Op:2000)

Travel of boring spindle (W axis): 800

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Product introduction

TK series is one of floor type boring and milling machines, boring spindle diameter is 130mm,spindle speed is 2-800mm.travel of ram is 800mm.axial travel of spindle is 700. Floor Type Boring and Milling Machine is a machine equipped with advanced techniques such as mechanics, electrics and hydraulics. Many key techniques are adopted: Hydrostatic guide way (constant flow), No back-lash rack-pinion drive system, ram feed auto compensation, etc.

1.Machine Tool Introduction:

Series of T69/ TK69 digital display/CNC floor-type milling/boring machine is a kind of efficient advanced equipment with excellent properties, wide range of process scope, which can completely replace the double housing planer and landing boring machine.

This series of machine tools can be clamped in a large heavy work pieces and complete all kinds of drilling and milling boring machining. The plane and curved surface can be processed.

This series of machine tool is of a good rigidity, high precision, strong versatility, especially equipped with many kinds of special accessories (universal milling head, vertical milling head, elongation milling head, high-speed milling head, angular milling head, d-post rotary table, etc.) to further expand its application range.

2.The Main Structural Features:

1. Main transmission:

The main transmission of this boring and milling head adopts the square ram portable structure level and is one of the core parts of this machine. 2 the transmission system

2.Machine tool main drive:

Machine tool main drive by mechanical variable speed motor and speed regulating electrical appliances can obtain 2-560 - r/min1000 r (optional) the infinite speed range to meet the needs of various machining

3. Bearing:

Spindle bearing spindle system is the key components of the imported special customized bearings

Other bearings with name brand manufacturers products

4. The transmission structure:

X axis traverse by eliminating gaps for the double pinion and rack structure of the whole feed structure in a slide in the body and therefore good rigidity and transmission can be eliminate the clearance adjusting

Spindle box vertical feed (Y) with ball screw pair drive screw fixation in the first column on the feed motor through slow down gear drives the rotating spindle box to get the vertical feed

Z axis W axis driving principle of the ball screw vice same as Y-axis

5. Hydraulic and lubrication system:

Columns (X axis) mobile adopts hydrostatic slide friction coefficient is small

X Y Z axis of the guide surface are stick to plastic processing machine tool guide rail protection

Key components of the hydraulic system pump hydraulic valve parts were picked from domestic famous manufacturers of products with reliable work stability

Pillar square ram guide are adopted the measures to prevent oil spills

6. Locking and positioning:

X Y W axes have separate automatic locking mechanism locking mechanism and precession electrical interlocking

7. Parts:

Machine tool pillar spindle box of lathe bed square ram, etc big adopt high quality cast iron manufacturing integral rigidity and good seismic performance of shock absorption

8. Precision compensation system:

TK69 CNC floor-type boring and milling machine series adopts automatic gravity compensation system to ensure the balance of spindle box body and prevent slippery pillow moved forward when the main spindle box focus changes and make the spindle head

9. Guide:

Former pillar traverse spindle box for vertical feed and ram the axial feed adopts the static pressure guide rail machine precision has good damping shock absorption effect to keep good long life high reliability

10. Protective device:

The machine adopts the overall protective set spindle box adopts processing center type integral protection

Square ram with fixed protective cover at the back of the pillar bed way scalability protective cover can prevent contamination of guide rail damage and pollution

11. Platform:

At the side of the spindle box is equipped with the operating table walk along with the spindle box and move up and down movement also stood with mobile and mobile to achieve the purpose of convenient operation

12. Control station:

Machine adopt the way of catwalk centralized control button station operating hand-held unit is available in a wide range of mobile in order to achieve the purpose of convenient operation

3.Our Product Photo:

4. Our Foreign Trade Exhibition:

5. Other products you may interest in:

We are the big machine manufacturer specializing in producing heavy duty machine tools, it has five factories in China which mainly produce Vertical Lathe, Boring & Milling Machine, Heavy-duty Horizontal Lathe, both conventional and CNC types.

We have a group of professional engineers in charge of technology, manufacturing, installing and testing, so we can guarantee that our machines will put on good performance based on high quality. We can provide customers with full service and technical consultation upon different requests in 24 hours. R&C Machinery would like to offer its best machines with best solution, and build itself as the bridge and window for both overseas and domestic enterprises and customers.

7. Main Export Market:

Canada, the U.S.A., Italy, France, Brazil, Bolivia, Chile, Russia, Romania, Saudi Arabia, Syria, Jordan, the U.A.E., Indonesia, Singapore, Thailand, India, Pakistan, South Africa, Egypt, Nigeria, Kenya and so on.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China