Five Axis Simultaneous CNC Machine Center entered into our northeast .

time2019/11/13

- Five Axis Simultaneous CNC Machine Center entered into our northeast .

DRC Machinery Intelligence Technology is committed to replace the import of high-end machine tools!

Let the world change the perception of MADE IN CHINA, our small business have great significance!

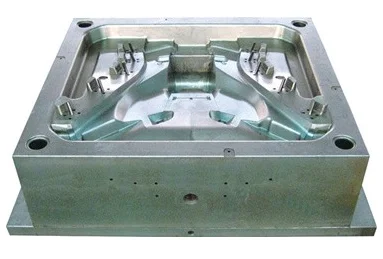

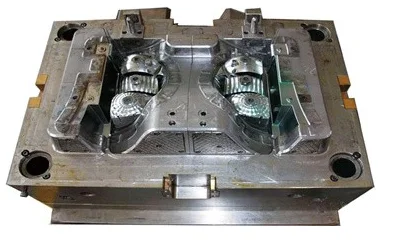

CNC machining center use

Cnc machine center vertical machining center less grinding machine used cnc vmc machine.

Vertical Machine Center adds five-axis turntables based on the advantages of rigid rigidity, structural symmetry and stability of the traditional vertical CNC milling machine. It introduces the international advanced dynamic rigid design concept and optimizes the design of moving parts. The machine tool has large torque and good fast response characteristics, and is suitable for various mechanical processing fields such as automobile, mold, aerospace, military, and hardware.

Cnc milling machine overall layout

The overall layout of the Vertical Milling Machine is the whole structure, the base is fixed, the boat seat is fixed on the bed; the slide is moved in the X direction on the boat seat; the bull head is moved in the Y direction on the slide; the ram is moved in the Z direction on the bull head; The turntable is fixed on the boat seat, and the workbench is rotated by B and C axes.

cnc vertical milling machining center

Precision five-axis vertical machining center

Structural features of the CNC Milling Machine

High rigidity and long-term precision retention

1, cnc vertical machining center main large parts: base, boat seat, slide seat, cow head, ram are made of high quality resin Sand molding, high-strength high-quality cast iron, complete heat treatment process to eliminate residual stress, and arrange enough reinforcing ribs to ensure sufficient strength, rigidity and high stability of the machine;

2. The B and C axes adopt the Italian imported turntable. The turntable has high precision, good repeat positioning accuracy, adjustable worm and worm clearance, and convenient maintenance.

3, the three-axis adopts roller linear guide, which has strong rigidity and good dynamic precision;

4. The three-axis transmission adopts Taiwan brand grinding double nut ball screw, which has compact structure, stable movement and high precision. The screw support is supported by a precision screw rod, pre-stretched at both ends, eliminating the loss of precision caused by thermal elongation, and forming a stable high-rigidity mechanical transmission system;

5. The base adopts a large water tray structure for casting, which has good waterproof performance;

6, high rigidity Taiwan brand BT40 spindle, lubricated with grease, can make the spindle bearing Constant and reliable lubrication, both economical and environmentally friendly, and long-term maintenance-free;

High precision, high dynamic response

1. The spindle adopts high-precision angular contact ball bearing, so that the spindle obtains high rigidity and obtains extremely high spindle rotation precision;

2, three-axis roller linear guide, high precision and large load. Low friction, reduce low-speed crawling of the machine tool, good positioning accuracy, and high dynamic response characteristics;

3, high efficiency

The spindle speed can reach 15000rpm, and the three-axis rapid movement can reach 36/36/36m/min;

4, the processing range is large

Compared with the same specification machine, the machine's stroke parameters ensure a wider processing range.

5. Fully enclosed protective cover with pleasant operation and beautiful appearance

The protective cover made by the professional sheet metal factory has an observation window and is pleasant to operate.

Large Vertical CNC Machining center

Design

Through the mechanical design, design of finite element method with the combination of modern design method, and combined with the machine heat source management technology and ergonomics design technology, can to be the high rigidity, high electrical rigidity, high reliability, excellent thermal stability.

Technology

Thermal stability of the structure design, the machine heat source management technology and the perfect combination of thermal compensation technology, to further improve the accuracy of machine tool stability

Structure

The perfect combination of motor and screw. Maximize electrical power utilization, so that the machine motor power consumption optimization

Energy saving

Increase the machine tool spindle, tool storage, lubrication, chip device, hydraulic station energy saving mode, so the power consumption dropped by 30%. Precision five-axis vertical machining center

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China