An Engineer's Guide to CNC Turning Centers

time2017/06/19

- The lathe is one of the oldest manufacturing technologies on Earth. The earliest versions date all the way back to the ancient Egyptians, who invented a two-person, bow-driven lathe around 1300 BCE. Yet despite this venerable history, turning technology has been far from static, as evidenced by the sophisticated CNC turning centers of today

The lathe is one of the oldest manufacturing technologies on Earth. The earliest versions date all the way back to the ancient Egyptians, who invented a two-person, bow-driven lathe around 1300 BCE. Yet despite this venerable history, turning technology has been far from static, as evidenced by the sophisticated CNC turning centers of today.

Turning Center Basics

Lathes vs. Turning Centers: What’s the Difference?

You’ve probably seen the terms ‘CNC lathe’ and ‘CNC turning center’ used interchangeably.

Nevertheless, while there is no formal distinction between lathes and turning centers, the former term is often used to refer exclusively to simpler machines—those designed for turning operations alone. In contrast, the term ‘turning center’ usually denotes machines which integrate milling or drilling capabilities, or those with sub-spindles for performing secondary operations.

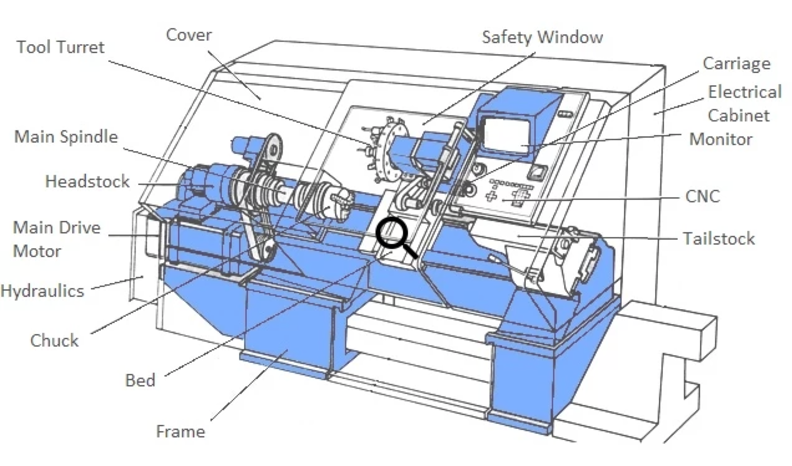

Headstock

The headstock houses the main spindle as well as the speed- and gear-changing mechanisms. The main spindle end often includes a Morse taper. In the early days of industrial lathes, the spindle was driven directly via a flat belt pulley. These days, it’s driven by an electric motor.

Bed

The lathe bed is a base connected to the headstock such that the carriage and tailstock move in parallel with the spindle access. This movement is facilitated by bedways, which restrain the carriage and tailstock in a set track.

Feedscrews and Leadscrews

The feedscrew is a long driveshaft that connects to a series of gears in the apron in order to drive the carriage along the Z-axis. The leadscrew has the same function but operates orthogonally to the feedscrew, moving the carriage along the X-axis.

Feedscrews and leadscrews are manufactured to either imperial or metric standards, which can cause compatibility issues between workpieces made on different lathes.

Carriage

The carriage holds the cutting tool and moves it longitudinally to the workpiece for turning operations or perpendicularly for facing operations. The carriage is composed of two castings: the top, or saddle, and the side, or apron.

Tailstock

The tailstock refers to the center mount which is positioned opposite to the headstock. In contrast to the headstock, the spindle in the tailstock—which can include a taper to hold drill bits, centers or other tooling—does not rotate. Instead, it travels longitudinally under the action of a leadscrew.