An Engineer's Guide to CNC Turning Centers

sourcehttp://www.engineering.com

time2017/05/27

- The lathe is one of the oldest manufacturing technologies on Earth. The earliest versions date all the way back to the ancient Egyptians, who invented a two-person, bow-driven lathe around 1300 BCE. Yet despite this venerable history, turning technology has been far from static, as evidenced by the sophisticated CNC turning centers of today.

Read on for an overview of the components, types, operations and applications of CNC turning centers.

The lathe is one of the oldest manufacturing technologies on Earth. The earliest versions date all the way back to the ancient Egyptians, who invented a two-person, bow-driven lathe around 1300 BCE. Yet despite this venerable history, turning technology has been far from static, as evidenced by the sophisticated CNC turning centers of today.Read on for an overview of the components, types, operations and applications of CNC turning centers.

Turning Center Basics

Lathes vs. Turning Centers: What’s the Difference?

You’ve probably seen the terms ‘CNClathe’ and ‘CNC turning center’ used interchangeably.

“[They’re] basically the same thing inmy book,” said David Fischer, lathe product specialist at Okuma America Corporation.

| Nevertheless, while there is no formal distinctionbetween lathes and turning centers, the former term is often used to referexclusively to simpler machines—those designed for turning operations alone. Incontrast, the term ‘turning center’ usually denotes machines which integratemilling or drilling capabilities, or those with sub-spindles for performingsecondary operations. |

“In my opinion, a CNC lathe juststrictly does turning; it’s a 2-axis lathe with X and Z axes and typically onlyone chuck,” said Rick Bramstedt, product manager for Mazak’s Advantec division. “A CNC turning center has millingcapability, or a second spindle plus milling capability, and so it might have aY-axis as well. We also call those Multi-Tasking Machines. That’s how I seeturning centers: they offer more than just turning.”

Marlow Knabach, Chief Technology Officerfor DMG MORI USA, agreed:

“I see it as the evolution of thelathe,” he said. “Most people called it a lathe in the past, but as CNC becamemore elaborate and with the addition of milling and sub-spindles, it evolvedinto a CNC turning center.”

Whether you’re workingon a lathe or a turning center, the basic parts are the same.

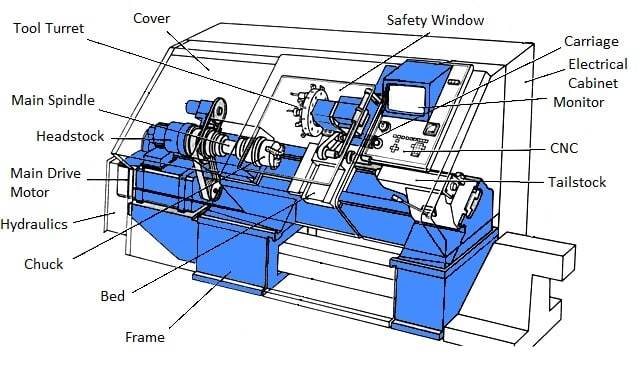

Headstock

The headstock houses the main spindle aswell as the speed- and gear-changing mechanisms. The main spindle end oftenincludes a Morse taper. In the early days of industrial lathes, the spindle wasdriven directly via a flat belt pulley. These days, it’s driven by an electricmotor.

Bed

The lathe bed is a base connected to theheadstock such that the carriage and tailstock move in parallel with thespindle access. This movement is facilitated by bedways, which restrain thecarriage and tailstock in a set track.

Feedscrews and Leadscrews

The feedscrew is a long driveshaft thatconnects to a series of gears in the apron in order to drive the carriage alongthe Z-axis. The leadscrew has the same function but operates orthogonally tothe feedscrew, moving the carriage along the X-axis.

Feedscrews and leadscrews aremanufactured to either imperial or metric standards, which can causecompatibility issues between workpieces made on different lathes.

Carriage

The carriage holds the cutting tool andmoves it longitudinally to the workpiece for turning operations orperpendicularly for facing operations. The carriage is composed of twocastings: the top, or saddle, and the side, or apron.

Tailstock

The tailstock refers to the center mountwhich is positioned opposite to the headstock. In contrast to the headstock,the spindle in the tailstock—which can include a taper to hold drill bits,centers or other tooling—does not rotate. Instead, it travels longitudinally underthe action of a leadscrew.

Turning Center Operations

There are many operations that can beperformed on a lathe, and even more that can be performed on a turning center.Here are some of the most common:

Facing

Facing operations are used to produceflat surfaces on the end of a part.

Threading

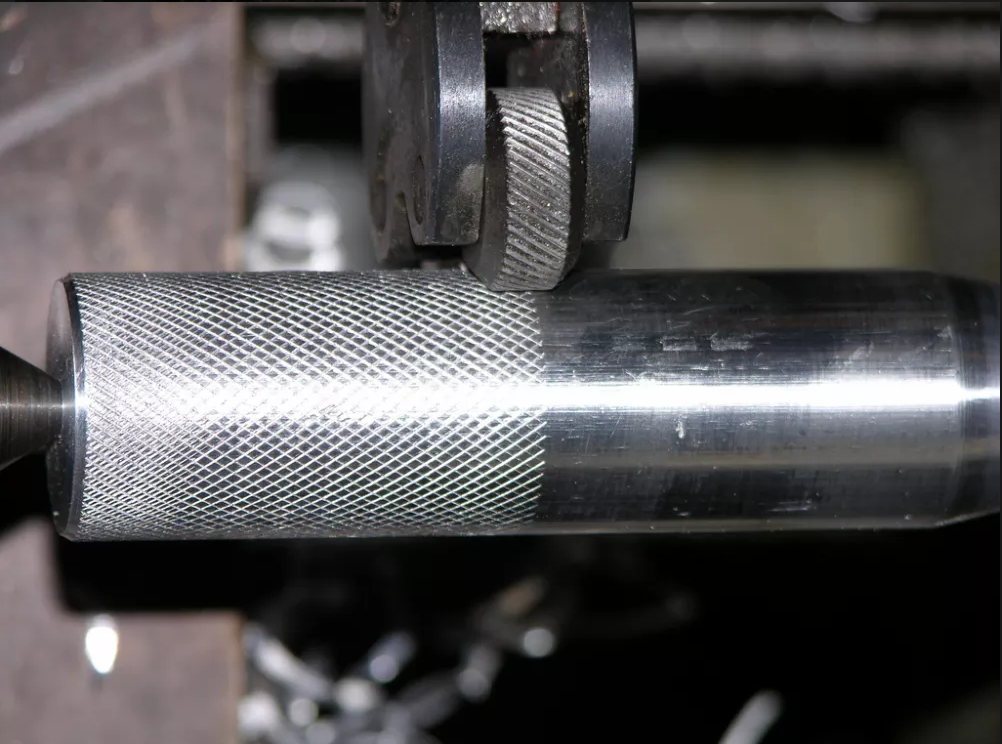

Knurling

Knurling operations are used to producea regularly shaped roughness on cylindrical surfaces.

Drilling

One of the most basic operations,drilling is used to generate holes in workpieces.

Boring

Boring involves enlarging a hole orcavity to produce circular, internal grooves.

Reaming

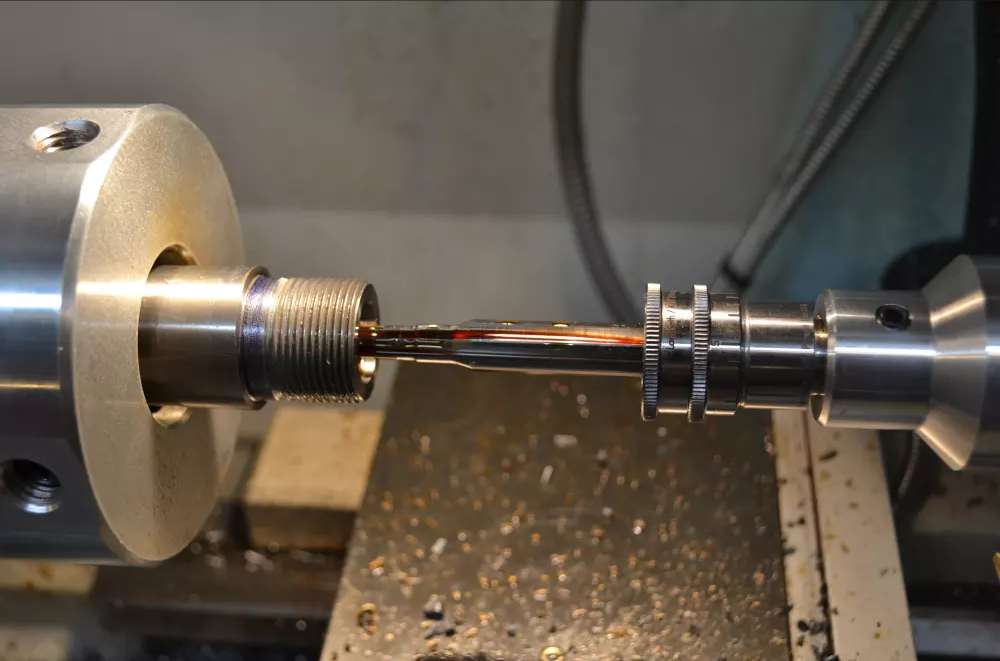

Taper Turning

In taper turning, the diameter of theworkpiece is gradually reduced over the length of the part.

Turning Center Configurations

“You have essentially two differenttypes of CNC machining centers: the traditional, horizontal type that’s beenaround for quite some time, and then you have the vertical type, which spinsthe part like a top instead of spinning it like a car tire,” said JamesPetiprin, key account manager for EMAG, LLC.

“Horizontal probably makes up 60 or 70percent of the market because it’s been around longer—every machinist learnedon a horizontal lathe.”

CNC turning centers come in eitherhorizontal or vertical configurations. There are also inverted vertical turningcenters, which reverse the position of the spindle and the chuck. All threemachine types generally consist of the same basic components (i.e., headstock,carriage, etc.), but differ in their orientation. Deciding whether to opt for ahorizontal, vertical or inverted vertical lathe depends on a host of factors,but there are some rules of thumb that can help you make the decision.

“The advantage with a horizontal latheis that gravity pulls the chips away from the part,” said Knabach. “In otherwords, as you’re turning, all the chips fall down into the chip conveyor orbin.”

“The advantage of avertical lathe is that gravity helps seat your part into your workholding,” hecontinued. “But the chips can be an issue, especially if your part is concave,since it can trap the chips internally. So you have the possibility ofre-cutting your chips. The other concern with a vertical lathe is that thechips fall down into the spindle itself, so your guarding has to be extremelyefficient.”

“Generally, horizontal lathes are moreflexible since they can have longer bed lengths relative to spindle size,” saidFischer. “They can also use barfeeders and commonly have tailstocks, a rarityon verticals. On the other hand, if you are machining large diametershort parts, especially if they are heavy parts, the vertical lathe workswell.”

“It’s primarily partsize; that’s the biggest factor that determines between the two,” saidBramstedt. “When we look at small turning applications, a lot of automotiveturning applications (transmission gear blanks, brake rotors, etc.) are donevertically and typically with a twin spindle. One benefit of that is that youhave gravity working for you; when you put the part in the chuck, it seatsitself. Another benefit is chip flow, again thanks to gravity—all the chipstend to fall away from the part into the pan or conveyor.”

“I’ve seen 30-inch diameter parts run ona horizontal machine,” he added, “but loading it is tricky because you need topush the part into the chuck and then hold it while you’re clamping it.”

Another factor to consider when choosingbetween horizontal and vertical configurations is the extent to which yourturning center will be automated. “Horizontal lathes are usually easier [toautomate] since the spindles and/or tailstock are at opposite ends of themachine and the turret can be positioned in such a way as to present minimalclearance issues,” said Fischer.

Bramstedt offered adifferent opinion: “As far as automatic loading, vertical is probably thepreferred method because of chip flow and because you don’t need the robot topush the part in order to seat it.”

Regarding inverted vertical lathes,Petiprin noted that, “Inverted vertical gives you a built-in automation thatyou don’t have on a horizontal, since the spindle comes over and picks up thepart, whereas in a horizontal you need a robot or gantry to load the part.”

Is inverted vertical turning right for you? Follow thelink to find out.

“CNC turning centers today are used inmost metal cutting environments—whether it’s automotive, aerospace,agriculture,” said Knabach. “Any component that has a high degree of roundparts—any type of a gear—usually is machined on a turning center at leastblank, prior to machining any of the gears.”

“You really find turning centers in allindustries,” said Petiprin. “EMAG’s business is 85 percent automotive. If youbreak automotive out, there’s transmission and driveline since they have themost round parts, and if you’re using a lathe you’re turning round parts.”

On the chip-making side, a subject offrequent debate amongst manufacturing professionals when it comes to CNCturning centers concerns the choice between turret tooling and gang tooling.

Turret tooling involvesmounting a set of cutting tools on a rotating, indexable toolholder. Incontrast, gang tooling involves setting up a row of tools inside the lathe on across-slide, which is similar to the table on a milling machine.

Deciding which configuration is best foryou depends—as always—on your application, but there are some rules of thumbthat can help you make your decision.

“Generally, gang tooling is more usefulon small lathes cutting small parts, using a limited number of tools,” saidFischer. “Gang tooling works well in these situations because the cycle timecan be minimized since the turret index time is eliminated. Also, toolchange-over time can be reduced to nearly zero since the tool plates can beswitched out quickly for each job.”

Bramstedt agreed: “That’s the primaryreason for choosing gang tooling: dedicated, high-volume parts.

“A turret can give you12 tools, but it takes a tenth of a second or half a second to index each tooland you typically have to come off of the part to do that. That costs cycletime, but it’s also very flexible—you can keep the same 12 tools in there andjust reprogram the machine to cut a different part.”

“The advantage to a turret is that youusually have a much larger work envelope, so you have less interference fromtool to tool,” said Knabach, “which allows you to maintain a larger diameterwith a turret, as opposed to gang tooling. Of course, it’s determined by theconfiguration of the machine, but generally speaking, gang tooling is muchcloser together and therefore you have a smaller interference zone.”

“A turret permits greater toolingclearance and generally works better for larger parts,” Fischer added. “On turrets, quick change tooling can be used on each individual station tospeed up change-over, but it won’t be as fast as changing out the tool plate.”

Knabach agreed. “In today’s technology,it’s pretty short—you’re talking a second or less—but if you have a lot oftools then that can still count up, especially if you’re looking at near net shapeturning,” he said.

This means that if you’re going forhigh-volume, it’s generally better to opt for gang tooling in order to minimizecycle times. “We offer a couple of gang machines,” said Bramstedt. “But thoseare typically dedicated to high-volume parts because of that half a secondturret index time.”

On the other hand, if your primaryconcerns are changeover and flexibility, turret tooling may be the betteroption. “Changeover is very long on a gang machine,” commented Bramstedt,“because you have to position the tools, probe them, make a test cut, move thema little and take another test cut, etc. Whereas with a turret, you load thetools, touch off your tool setter and you go.”

Many CNC turning centers can be equippedwith live tooling, i.e., rotary cutting tools powered by independent electricmotors. This makes it possible to drill holes in a part perpendicular to themain axis, which can be extremely useful. Does that mean live tooling is alwaysworthwhile?

“Live tooling reallyhas revolutionized the lathe, especially at DMG MORI,” said Knabach. “We havetechnology where we incorporate a direct drive motor inside our turret. Aconventional drive mechanism would rely on gears or a belt and pulley to drivethe tool, but with ours it’s an integral spindle.”

“Live tooling is often one of thosethings that you don’t realize how great it is until you actually use it,”agreed Fischer. “Once customers gain some experience with it we often seethem add the Y-axis as well to provide even more capability and flexibility.”

“If I’m doing a bearing race or abearing cone—something where you don’t need to drill any holes—then I won’tneed rotary tooling,” said Bramstedt, “But other than that, I can’t reallythink of any cases where it wouldn’t be useful.”

Fischer agreed: “There are, of course,certain situations where it is better to break out the individual processes butthese cases are fewer and fewer. As lot sizes get smaller and machinecapabilities get better (and faster), the need to break out processes isreduced.”

“The benefit of live tooling is that itreduces work-in-process, which is dollars in your pocket,” said Bramstedt. “IfI have to turn this part on a lathe and then take it off to cut a keyway, Ihave to put that on a vertical machining center, so now my part is sitting on askid while I set that up.”

“We actually have somecustomers in applications where they’re not even using the lathe for turning,”said Knabach. “They’re using it as an automated production center with a barfeed, feeding the bar into the machine and perhaps never turning on the turningspindle, but just using the live tools as a machining center. They might usethe turning spindle only to turn the bar long enough for the cut off operation.Then you can use your parts catcher or overhead gantry, whichever’s required,and now it’s a fully automated system from a simple lathe with live tooling andperhaps a Y-axis.”

With the dawn of Industry 4.0, automated machining is becoming more widespread.CNC turning centers are no exception, although automating a CNC lathe dependson the configuration of the machine (Vertical vs. Horizontal vs. InvertedVertical).

“A horizontal lathe istypically loaded by a manual operator, so for automation you go with a robot ora gantry—something that would pick it up from a known location and then put itin the chuck,” explained Petiprin. “You want to utilize 80 percent of therobot’s time, so that usually means you can split two machines between onerobot, though if you have a shorter cycle time then you’ll need one robot permachine.”

“Generally horizontal lathes are easiersince the spindles and/or tailstock are at opposite ends of the machine and theturret can be positioned in such a way as to present minimal clearance issues,”Fischer added. “Either way, all of our machines have been automated in manydifferent configurations.”

Although CNC turning centers are just asamenable to automation as other machine tools, there are some importantdifferences between automating a lathe and automating a machining center.

“The fixturing or theworkholding is the biggest difference,” said Bramstedt. “We’ve automatedmachining centers on a regular basis, but you’re typically loading into sometype of special fixture with automatic or even sequential clamping. It’s a muchmore complicated fixture and typically dedicated to a part. That’s opposed to alathe, where I can load a variety of different parts with just a three jawchuck. It’s very flexible as far as workholding goes.”

In manufacturing, mistakes andbottlenecks in efficiency are to be avoided at all costs. This holds true evenfor a technology as old as the lathe, though the advent of computing inmanufacturing has gone a long way toward minimizing these issues.

“Believe it or not, I still hear aboutpeople who have manual lathes in their shop,” Bramstedt commented. “This istheir first CNC and it just amazes me that they can be competitive.”

Fischer offered a very differentperspective:

“A seasoned veteran machinist (who alsohappened to be my dad) once told me that no matter how many CNC lathes a shophad, they would always keep at least one manual engine lathe and that is truehere where we have two manual Okuma lathes still in service.”

One of the major limitations on latheefficiency lies in the turning operation itself. This is not an issue that canbe overcome with better tooling, as Bramstedt explained:

“Machine tools are always trying tocatch up to tooling capabilities. You might be able to cut at X amount ofsurface speed, but I can’t spin my chuck fast enough to generate that kind ofsurface speed. With turning, your rpm is limited because of chuck gripcapabilities. The centrifugal force means that as the chuck is spinning around,the jaws want to move outward. On a machining center, the part is stationaryand my tool—which is very compact—can be spun at 10, 12, 20 or even 40,000 rpmwithout big issues. There’s no way you can spin a chuck at 40,000 rpm; it wouldjust come apart.”

Another bottleneck for turningefficiency is one which applies to most manufacturing processes:changeover.

“Depending on lot sizethe importance of change-over varies,” said Fischer. “For a shop that doesshort run production, change-over is critical and your workholding and toolingsystems must be carefully considered. These things take away from theavailable production time of the machine.”

This raises the issue of programprove-out, which can be time consuming, though there are ways to reduce it. “Byhaving good simulation software and utilizing Okuma’s Collision Avoidance System(CAS) the prove-out time can be minimized and the machine is protected fromoperator error,” Fischer commented. “And nothing eats into your production timelike a machine crash!”

Maximizing efficiency is one goal in manufacturing,but that goes hand in hand with minimizing mistakes. Bramstedt and Fischer eachpointed to different sources of error when it comes to using CNC turningcenters.

“Some customers want tomaximize feeds and speeds, so they crank it up to run 20 percent faster,” saidBramstedt. “They can do that, but then they have to stand there and wait forsomething to explode, whereas if they back off a little bit they can walk awayfrom it. That’s not to say nothing will happen, but the chances of unexpectedtool failure are minimized because we’re not pushing it to the maximum. We havea lot of unattended cells here at Mazak where we do just that. Cycle times willbe slower, but at the end of the month the throughput is better.”

Fischer emphasized the importance oftraining: “You are placing a high-tech piece of equipment in the hands of anoperator/setup person/programmer. Invest in training these people so that theycan perform at a high level.”