CNC Vertical Machining Center Manufacturers Products In The Maintenance Procedures Must Follow The P

General vertical machine center

General vertical machining center, mainly used in medium-sized parts and molds, the workpiece in a fixture may be for the completion of milling drilling boring, reaming and other processes of processing, it can be single used and can also be used for multiple operations on parts in a production line. Cutting with powerful, high-speed positioning. mechanical and electrical integration, automatic chip control and security protection features.

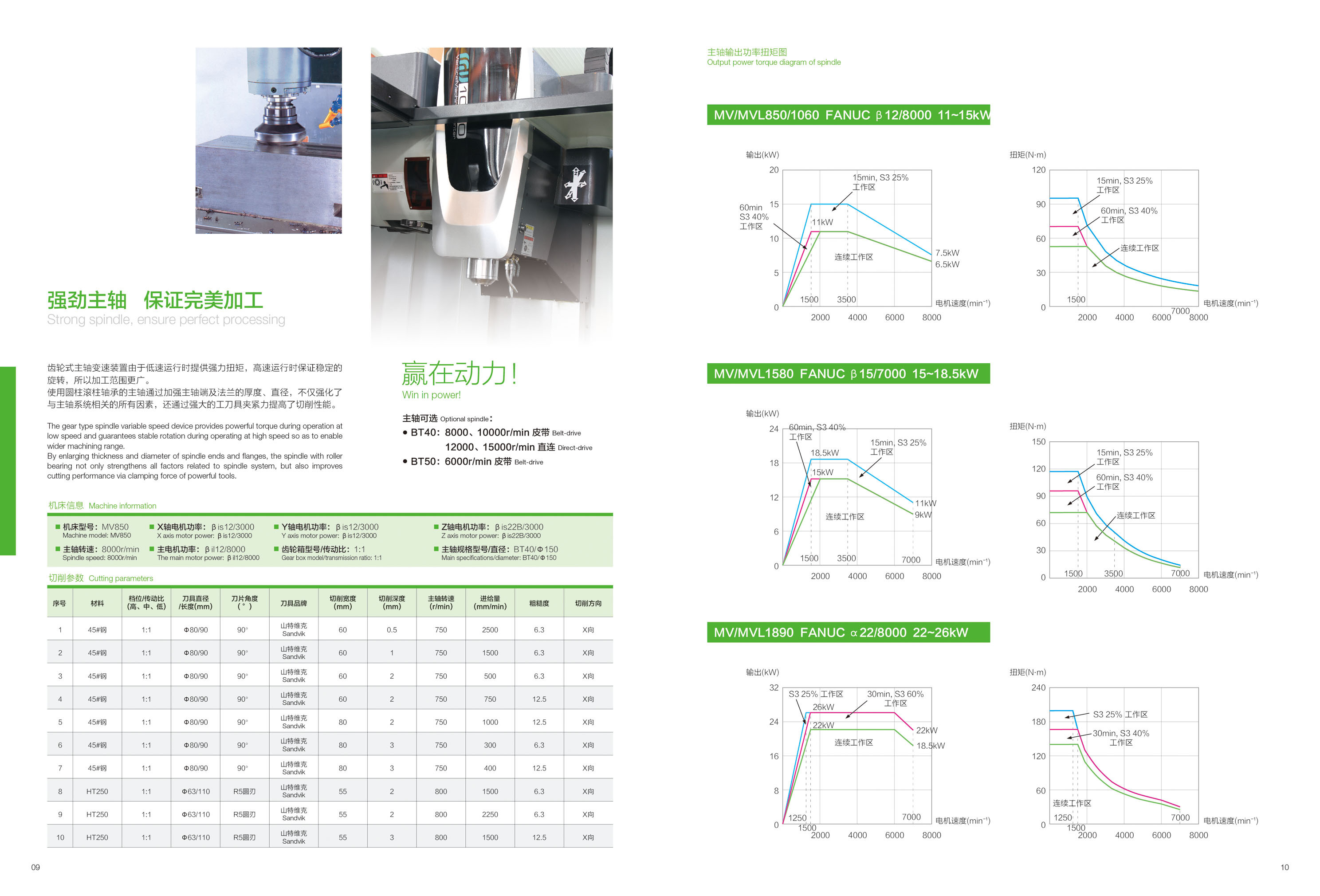

Strong spindle, ensure perfect processing:

The gear type spindle variable speed device provides powerful torque during operation at low speed and guarantees stable rotation during operating at high speed so as to enable wider machining range.

By enlarging thickness and diameter of spindle ends and flanges, the large specifications bearing not only strengthens all factors related to spindle system, but also improves cutting performance via clamping force of powerful tools.

High Accuracy Vertical Turret Milling Machine MVL1165S CNC Machining Center with Tool Magazine

Strong spindle, ensure perfect processing

The gear type spindle variable speed device provides powerful torque during operation at low speed and guarantees stable rotation during operating at high speed so as to enable wider machining range.By enlarging thickness and diameter of spindle ends and flanges, the spindle with roller bearing not only strengthens all factors related to spindle system, but also improves cutting performance via clamping force of powerful tools.

Win in power

Optional spindle:

BT40:8000/10000r/min Belt-drive 12000/15000r/min Direct-drive

BT50:6000r/min Belt-drive

1. 3 line mechine standard nitrogen balance.

2. Optimal extension ratio of spindle box realizes the optimal machining rigidity.

3. Full-gear spindle transmission is optional.

4. Germany ZF gearbox is optional.

5. Design of large-span herringbone columns guarantees strong rigidity of columns.

6. Optional heightening pad below 300mm. Above 300mm, the column integral heightening.

7. Above the 1680 series, the bed bring their own horizontal automatic spiral chip.

8. Above the 1370 series, standard roller guide. Other types optional roller guide.

9. Above the 1680 series, is the inverted "T" shaped structure,table full support structure to ensure accuracy and atability.

10.With patent technology, the pedestal and water pan are cast into a whole, and water retaining steps are designed at the junction with metal plates to eradiate possibility of water seepage and leekage.

11.Block saddle Motor, overall type, to improve the transmission rigidity.

High Accuracy Vertical CNC Machining Center with Tool Magazine

Tool System:

Automatic toolchanger is composed of tool magazine and tool changing arms. Automatic toolchanger is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic toolchanger and other reasons on precision. Tool selection adopts the method of fixed address in the shortest path, All tools return to original position, therefore, the problem of collision between large-size tools is only considered in initial installation.Two-way tool magazine adopts the shortest path.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China