How Is The Price Of The Vertical Lathe Machine Determined?

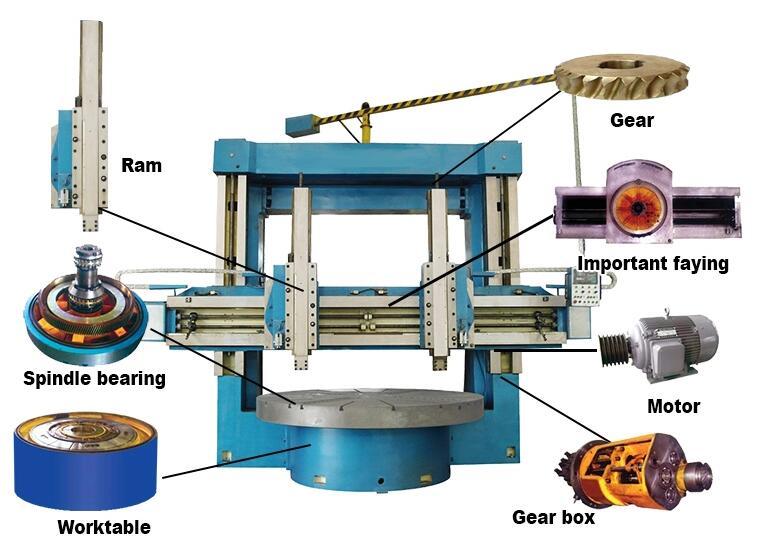

High Accuracy Double Column CNC Heavy Duty Vertical Lathe Main Features

1.The main shaft of workbench is centered by biserial short cylindrical roller bearing with high precision and adjustable diametral clearance.With the constant current and static pressure rack in axial direction,the workbench has the features of high running accuracy,large carrying capacity and small thermal deformation.

2.The pedestal ,workbench,lathe body and beam are made of ferrosteel with high strength and high wearing qualities ,which are tempered to remove the internal stress and to keep their shape from changing .

3.Scraped with hands,the guide surfaces of lathe body,beam and ram have good interface and high accuracy.With hydraumatic too -spot locking to the beam ,The lathe can keep still without tremble when feeding is large .

4.Scraped by hands ,the guide surfaces of upright column,beam and ram have high accuracy and good quality.

5.The feeding of the lathe is driven by AC servomotor through ball screw transmitting motion .The beam and vertical tool posts are covered with sealing shield ,which make the lathe more safe and easy to operate.

6. Table by table, table base, the main shaft device and institutions.

7. Portal frame is composed of left and right column and the connecting beam.

8. Beam by beam, horizontal feed drive structure, the clamping mechanism and hydraulic equipment, etc.

9.The left and right vertical tool rest by beam slide, the rotary slide, ram, transmission mechanism and hydraulic system.

10.Transmission driven by ac motor via a 10 6 gearbox, main motor 10 6 obtained with adjustable magnetic pressure regulating speed control, transmission speed driven by hydraulic system.

Machine Parts:Worktable

Workbench center is equipped with a larger unloading bearing, bearing capacity when the workpiece large tonnage, center unloading bearing with static pressure guide rail support workpiece rotate at the same time

Main Features: Beam

By the main body of the beam, and transmission mechanism of the beam, and unloading device, clamping device, hydraulic equipment, beam is made of HT250 cast iron material

Machine Parts:Lift and Right Turning Tool Rest

Two Vertical Toolrest install on the Beam, Left toolrest is CNC toolrest adopt Siemens 828D control system.

Main Features:Double Ram

This machine for double-column gantry frame structure.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China