Laser or machine tool business life straw?

Optical fiber transmission, flexible processing, suitable for cutting all kinds of metal materials such as stainless steel, carbon steel, aluminum, brass, copper and all others;Laser, cutting head, reducer, gear, rack and so on.

The key components are imported famous brands;Gantry structure, high stability of the machine, high-strength high-rigidity aluminum alloy beams;

Low operating costs and optical maintenance-free;

simple and intuitive system interface,high speed and high accuracy,high cost performance, easy operation and convenient operation.

cnc fiber laser cutting machine DRC Laser Cutter Laser Cutting Machine For SS Sheet/Carbon Steel/Metal

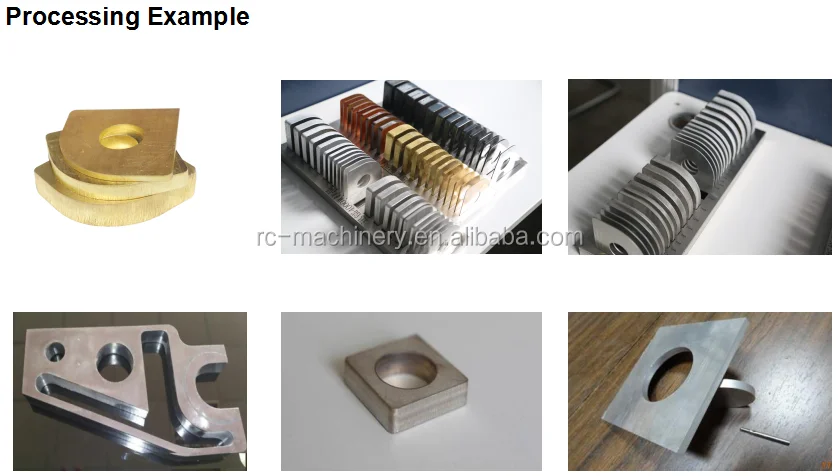

Applicable materials: Non-contact rapid cutting, hollowing and punching of various metal materials such as carbon steel plate, stainless steel plate, alloy steel, manganese steel, galvanized sheet, pipe, non-ferrous metal.

Laser cutting is the best cutting method in the cutting technology that people have today. Compared with traditional cutting, the advantages of laser cutting are:

1. Small thermal deformation, high cutting precision, low noise, no pollution, easy to achieve independent cutting, high cutting efficiency, and processing cost is reduced by 50% compared with machining.

2. Laser cutting has the advantage that traditional cutting can't replace, it will become the mainstream product in the cutting industry;

3. The machine tool adopts precision CO2 welding, high temperature annealing to remove stress, no deformation imported high precision ball screw / rack and pinion drive, high precision linear guide;

4. It adopts imported servo motor drive, equipped with imported high-rigid precision reducer, machine equipped with automatic lubrication device, and dust removal and smoke exhaust device in the cutting area;

5. The modular structure of the laser has high performance and maintenance-free;

6. Professional cutting software, easy to operate, convenient and flexible, free to design a variety of graphics and text cutting.

Cutting head and follower part

1.Using US technology, coaxial blown auxiliary gas cutting to ensure cutting quality;

2.Cutting head with automatic calibration, scale display, easy manual focus, so that users can follow.

3.With high precision capacitive sensing automatic tracking system

Software System

Fiber Laser

CNC fiber laser cutting machine using US NLIGHT fiber lasers.

1.Simple process settings

2.Back reflection isolation

3.Industry-leading beam quality

4.>30% of the elector-optical conversion efficiency

5.M2 ≤ 1.3 single-mode and tailored BPP options