What are the advantages of the machining center compared to ordinary machine tools?

Features:

The machining center is a high-efficiency, high-precision CNC machine tool. The workpiece can be processed in multiple processes in one setup. It also has a tool magazine and automatic tool change function. These rich functions of the machining center determine the complexity of the machining center programming.

The machining center can realize the linkage control of three or more axes to ensure the machining of complex surfaces. In addition to linear interpolation and circular interpolation, the machining center also has various machining fixed cycles, tool radius automatic compensation, tool length automatic compensation, machining process graphic display, man-machine dialogue, fault automatic diagnosis, offline programming and other functions. .

The machining center was developed from CNC milling machines. The biggest difference with the CNC milling machine is that the machining center has the ability to automatically exchange machining tools. By installing different tools on the tool magazine, the machining tool on the spindle can be changed in one clamping by the automatic tool changer to realize various machining. Features.

The machining center can be divided into vertical, horizontal and composite machining centers. The main shaft of the vertical machining center is perpendicular to the table, and is mainly suitable for processing sheet metal and shell workpieces, as well as for mold processing. The spindle axis of the horizontal machining center is parallel to the table top. Most of its worktables are CNC rotary tables controlled by servo motors. In the workpiece clamping, multiple machining surfaces can be processed by the rotation of the table. Box type workpiece processing. The composite machining center mainly refers to the vertical or horizontal two spindles or the main shaft can be changed at an angle of 90° on one machining center, so that five faces can be processed in one clamping of the workpiece.

( More Detailed Picture of MV series Machining Center )

Strong spindle, ensure perfect processing

The gear type spindle variable speed device provides powerful torque during operation at low speed and guarantees stable rotation during operating at high speed so as to enable wider machining range.By enlarging thickness and diameter of spindle ends and flanges, the spindle with roller bearing not only strengthens all factors related to spindle system, but also improves cutting performance via clamping force of powerful tools.

Win in power

Optional spindle:

BT40:8000/10000r/min Belt-drive 12000/15000r/min Direct-drive

BT50:6000r/min Belt-drive

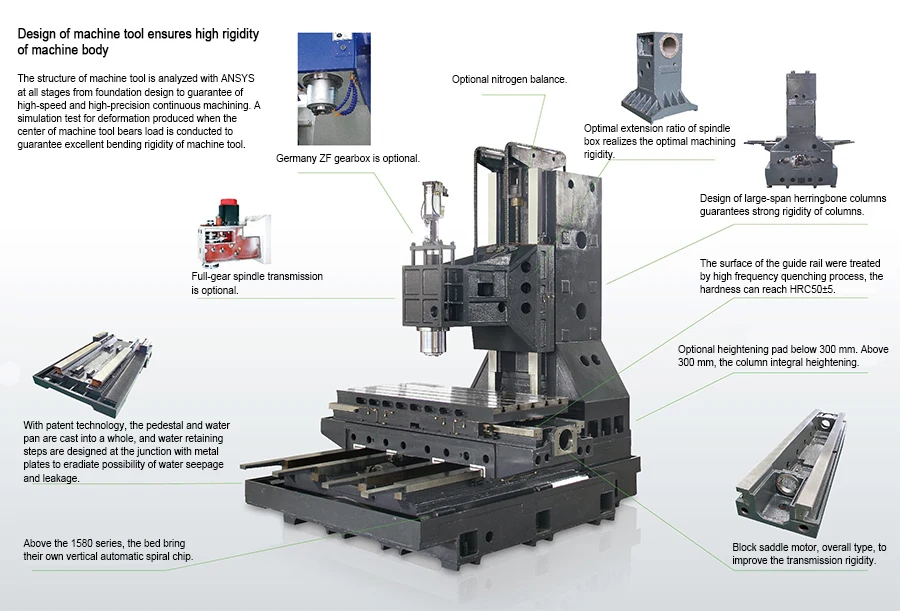

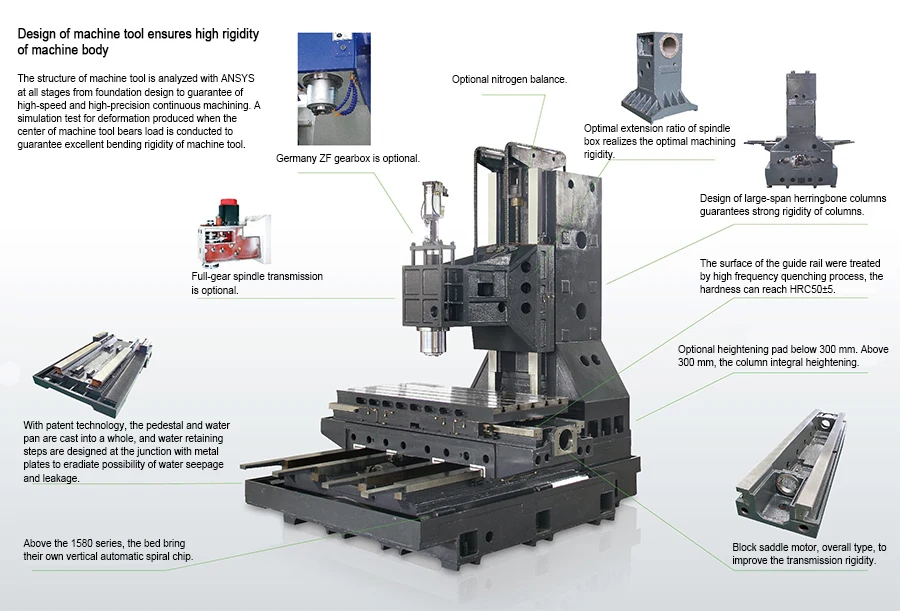

1.Design of machine tool ensures high rigidity of machine body

2.With patent technology, the pedestal and water pan are cast into a whole, and water retaining steps are designed at the junction with metal plates to eradiate possibility of water seepage and leakage.

3.Block saddle motor, overall type, to improve the transmission rigidity.

4.The surface of the guide rail were treated by high frequency quenching process, the hardness can reach HRC50±5.

5.Design of large-span herringbone columns guarantees strong rigidity of columns.

6.Optimal extension ratio of spindle box realizes the optimal machining rigidity.

Troubleshooting:

Fault 1: CNC encoder center serial encoder communication error alarm, reason: The unit detects that the motor encoder of the CNC machining center is disconnected or the communication is bad. Check that the motor's encoder feedback line is properly connected to the amplifier and is secure. If the feedback line is normal, replace the servo motor (because the motor's encoder is integral with the motor and cannot be disassembled), if it is an alpha motor, replace the encoder. If it occurs occasionally, it may be caused by interference. Check if the shield wire of the motor feedback line is intact.

Fault 2: CNC machining center encoder pulse count error alarm (LED display 6, system PMM screen display 303/304/305/308 alarm) Cause analysis: Servo motor serial encoder is lost during operation, or not counting . Turn off the power and turn it on again. If there is the same alarm, replace the motor (if the alpha motor replaces the encoder) or the feedback cable. If the alarm disappears after the CNC machining center is restarted, you must return to the reference point before running other commands. If the system's PMM is 308 alarm, it may be caused by interference, and then shut down and then turned on.