Inclined rail CNC lathes are now a very common type of machine

Inclined rail CNC lathes are now a very common type of machine

The oblique guide CNC lathe adopts a 45° oblique layout, and the bed is a tubular hollow structure, which greatly improves the bending and torsional rigidity of the machine tool during work. At the same time, after two aging treatments, the stability of the machine tool is improved, and the rigidity is high. The high-stability bed provides high-precision precision for the whole machine. The main spindle is an independent spindle unit. It is equipped with high-precision spindle special bearings. Lubrication uses imported special bearings to lubricate the tire. The overall spindle unit has small heat, good stability and precision. Good maintainability and maintenance free. The high speed of zui can reach 4500rev/min. The high precision, high speed and high efficiency of the spindle unit enable the whole machine to finish rough and finish machining.

Structural features of inclined rail CNC lathe:

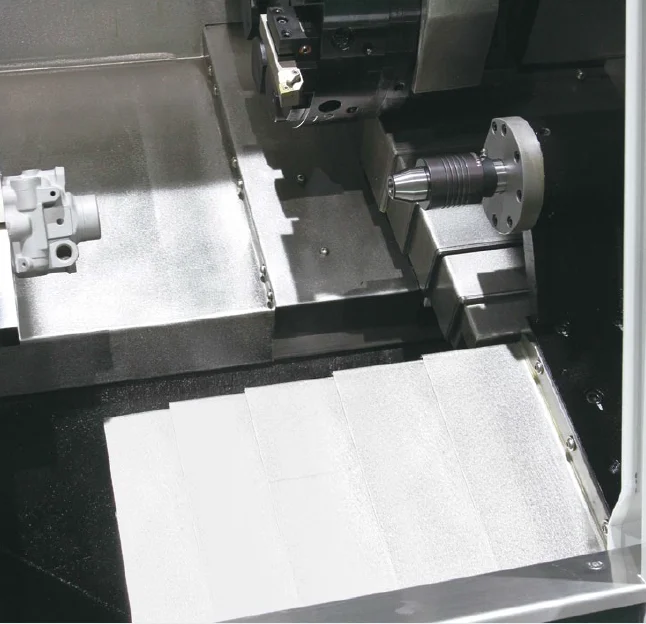

1. Mechatronics design, the bed and the foot are the whole structure, the bed is inclined backward by 45 degrees, the structure is compact, the rigidity is strong, the shock resistance is good, and the chip removal is convenient.

2. The inclined guide rail CNC lathe guide adopts centralized automatic lubrication device and fully enclosed protection, which is fully lubricated, safe and has a long service life.

3. The inclined guide rail CNC lathe spindle adopts the spindle unit, frequency conversion or servo main motor. The spindle speed is high and the stepless speed regulation can be realized.

4. The inclined guide rail CNC lathe drive adopts AC servo motor, which has high positioning accuracy and fast moving speed.

The inclined rail CNC lathe should do the necessary lubrication work:

1. In order to ensure the working precision of the inclined guide rail CNC lathe, adjust the anchor bolt or shock-absorbing leg during installation to ensure the level of the machine tool and not to twist the guide rail.

2. After the installation and commissioning work is completed, it is necessary to check whether the rotating part is flexible and whether the electrical circuit is reliable, and then carry out the running test. The test time is less than 2 hours, and the normal test can be entered before the test is completed.

3. The size of the inclined rail CNC lathe is equipped with a plug iron. After using for a period of time, the gap between the large and small carriages can be adjusted by adjusting the plug iron. It should be flexible in operation and does not affect the machining accuracy.

4. The sliding part of the inclined rail CNC lathe must be fully lubricated. Each shift (in 8 hours) should be filled with mechanical oil 2-4 times, and the bearing lubrication should be replaced every 300--600 hours.

5. The spindle bearing will have a gap after using the machine for a period of time. The user can adjust it according to the speed of use. If the clearance is too small, the bearing will be heated. The clearance will affect the accuracy of the workpiece. The surface roughness can be achieved by locking the front and rear bearings of the spindle. The tightening nut is adjusted tightly, and the clearance of the bearing is preferably kept at 0.006 mm.

6. During daily use, the user should do regular maintenance work. If the machine is finished, do the necessary cleaning work. Note: All operations must be in accordance with the relevant product manual. Situation, please stop using it immediately, and with professionals!

The inclined rail CNC lathe is a kind of machine tool which is very common in the machine tool industry. It is mainly used for the production and processing of instruments, electrical appliances, connectors, automobile and motorcycle parts, watches, glasses, photographic equipment, stationery, lighters, decorations and other accessories. It has internal and external thread and small high-precision spherical, tapered, and ultra-slim shaped workpieces.

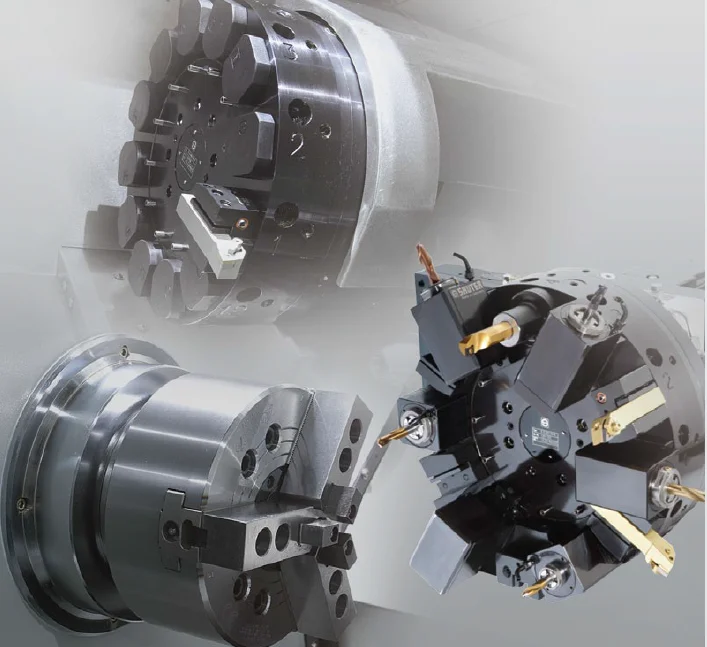

Rich configuration

Electric turret, servo turret, power turret; high-power motors, high torque. Motor; large diameter hollow cylinder; chuck; drawer-type water tank; on the knife;

Oil mist separator and other options are available.

User- friendly design

2. Processing conditions, all surrounded by human aesthetic design, stainless steel cover available for your safety

3. Full clean space, but also to guarantee the durability of the lathe.

Modern popullar control packages

IHT series have optional FANUC 0I TF control package & SIEMENS 828D control package. 8.4' display, 10.4 display, extra interfaces etc. ready for customers.

High cost performance

German descent i H T series has the best parts, like a knife tower SAUTER, NSK bearings, etc. to ensure high-precision parts, as well as appropriate should the price to have a high cost performance.