How to maintain the vertical lathe?

How to maintain the vertical lathe:

Extend the life of components and the wear cycle of components, prevent various faults, and improve the average trouble-free working time and service life of vertical lathes.

Precautions

1. Vertical lathe environment

Vertical lathes are best placed in a constant temperature environment and away from equipment with high vibrations (such as punching machines) and equipment with electromagnetic interference.

2. Power requirement

3. The vertical lathe should have regular operation and maintenance, and the fault should be recorded and protected.

4. Vertical lathes should not be stored for a long time

5. Pay attention to training and equipment operators and maintenance personnel

Maintenance of vertical lathe system

1. Strictly follow the operating procedures and routine maintenance system.

2. Preventing dust from entering the dust and metal powder floating in the electronic control device may cause the insulation resistance between the electrical components to drop, thereby causing malfunction or even damage to the components.

3. Regularly clean the cooling and ventilation system of the electric control cabinet.

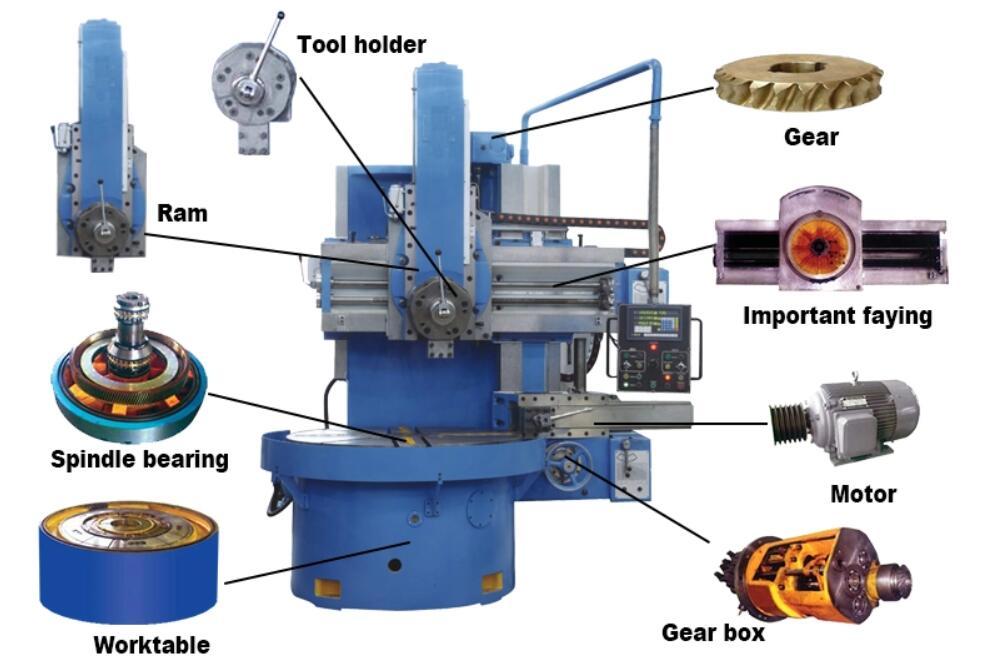

The single-column vertical lathe is a universal universal lathe in the vertical series. It is suitable for the outer garden, outer cone, inner hole, inner cone turning and drilling of various small and medium-sized ring parts, shells and flanges. Reaming, boring and other processing. It is worth mentioning that it is specially designed for the processing of the ball plate of steel ball equipment, and is also widely applicable to the processing of various disk parts.