What Is The Details Of MV series CNC Vertical Machining Center?

What Is The Details Of MV series Vertical Machining Center?

DRC Machining Center

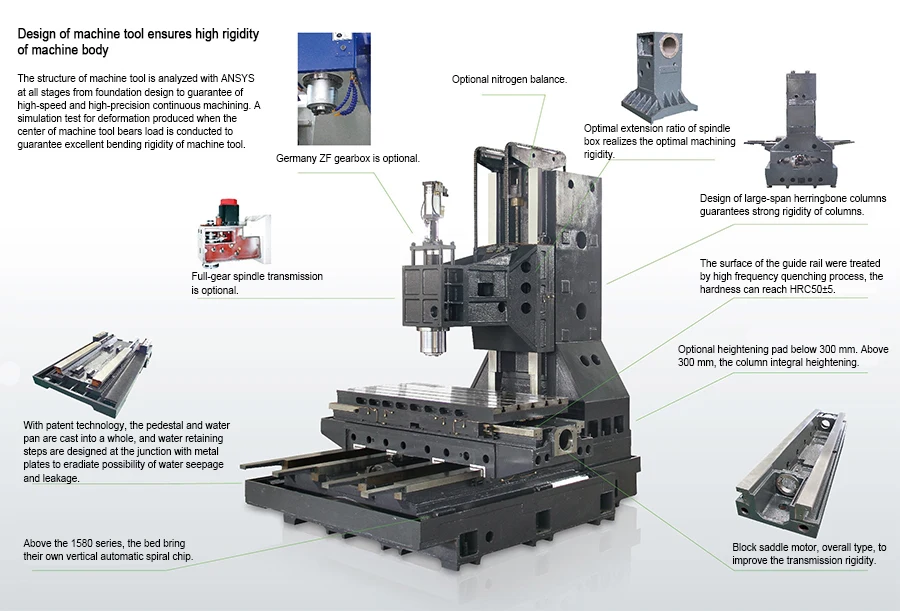

1.Design of machine tool ensures high rigidity of machine body

2.With patent technology, the pedestal and water pan are cast into a whole, and water retaining steps are designed at the junction with metal plates to eradiate possibility of water seepage and leakage.

3.Block saddle motor, overall type, to improve the transmission rigidity.

4.The surface of the guide rail were treated by high frequency quenching process, the hardness can reach HRC50±5.

5.Design of large-span herringbone columns guarantees strong rigidity of columns.

6.Optimal extension ratio of spindle box realizes the optimal machining rigidity.

Strong spindle, ensure perfect processing

The gear type spindle variable speed device provides powerful torque during operation at low speed and guarantees stable rotation during operating at high speed so as to enable wider machining range.By enlarging thickness and diameter of spindle ends and flanges, the spindle with roller bearing not only strengthens all factors related to spindle system, but also improves cutting performance via clamping force of powerful tools.

Win in power

Optional spindle:

BT40:8000/10000r/min Belt-drive 12000/15000r/min Direct-drive

BT50:6000r/min Belt-drive

MV series is line rail series, vertical machining center.Mainly used in medium-sized parts and molds, the workpiece in fixture maybe for the completion of milling, drilling, boring, it can be single used and can also be used for multiple operations on parts in a production line, Cutting with powerful, high-speed positioning mechanical and electrical integration, automatic Chip control and security protection feature.